DEUTZ introduces its first off-highway hybrid drive concept at Intermat

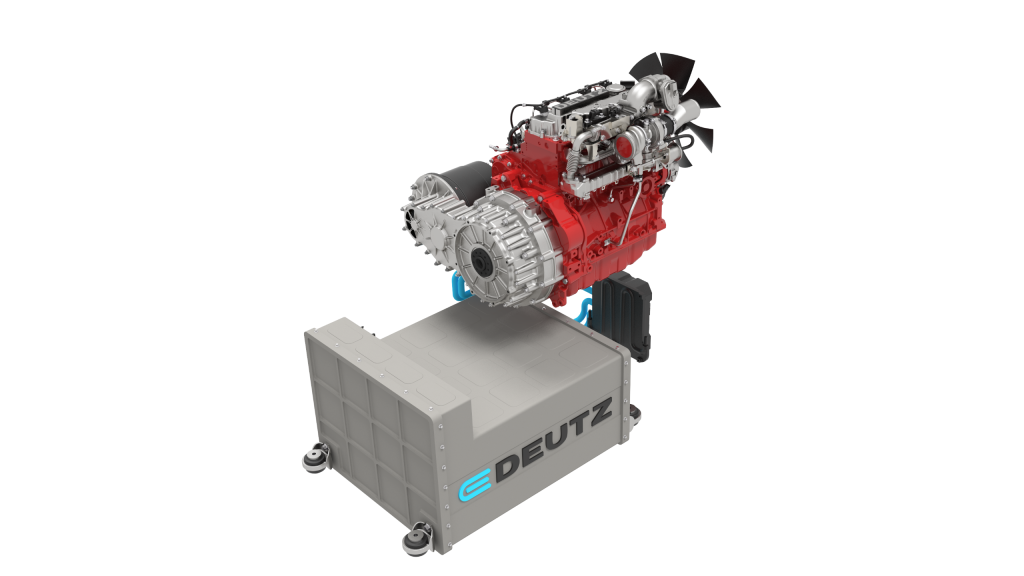

DEUTZ introduced its first off-highway hybrid concept at Intermat. Combining a TCD 2.9 diesel engine and a 55-kW electric motor, the new concept is the first tangible result of the E-DEUTZ program established in 2017, and opens up significant potential for efficiency gains in drivetrain technology. DEUTZ also presented an EU Stage V certified engine range and new in-line engines with capacities from 9 to 18 litres, while the service business presented its free service app ‘DEUTZ Connect' for remote engine diagnosis.

The E-DEUTZ strategy combines DEUTZ's low-emission engines with electric drives and its launch represents the company's next step forward. In September 2017, DEUTZ also acquired Torqeedo GmbH, a global market leader and system solution specialist for integrated electric and hybrid drives for boats. DEUTZ will harness Torqeedo's extensive know-how to benefit future developments in its off-highway business.

To illustrate this technology transfer at the Paris show, DEUTZ is displaying its concept of a modular, scalable hybrid drive consisting of a TCD 2.9 diesel engine and an e-motor, plus power electronics and a battery pack specially designed for this combination. The e-motor and diesel each deliver 55 kW, producing a combined maximum system output of 110 kW. The lithium-ion battery has a capacity of 40 kWh at 400 volts. The mechanical connection between the e-motor and the diesel engine is achieved by means of a transmission with integrated decoupler, which allows the diesel engine to be disconnected from the electrical system and provides the option of powering the vehicle purely by electricity. The increased maximum system output makes it possible to use a combustion engine with a lower capacity and output than a pure combustion drive in the same output class. A further benefit of hybridization is the option to integrate additional fuel-saving functions such as start-stop or crankshaft starting, and for power takeoffs to run on electricity in future.

As Chairman of the DEUTZ Board of Management, Dr Frank Hiller, explains, "The power output and capacity of each component can be scaled to meet customers' requirements. Customers will be able to choose whatever is the optimum combination of conventional and electric drive components for their particular application. Overall, this will increase efficiency and thereby significantly reduce total operating costs."

Visitors to the DEUTZ stand can see the modular E-DEUTZ system configuration on a tablet, via a digital product toolbox. TCO (total cost of ownership) illustrations show how quickly they can recoup the costs of investing in a hybrid drive. Depending on the customer application, this can be after as little as one year of use.

"Through the E-DEUTZ strategy, we are leading the way in the field of electrification and investing in cleaner and more efficient technology" says Frank Hiller. "We aim to be the market leader for innovative drive systems in the off-highway sector."

DEUTZ engine range: certified, extended and award-winning

In addition to the electrification of its drive systems, DEUTZ is demonstrating its expertise in exhaust aftertreatment. In 2017, DEUTZ was the world's first engine manufacturer to be given a certificate for the new EU Stage V emissions standard that comes into effect in 2019. The DEUTZ TTCD 6.1 received the first certificate and was followed by other models which were immediately marketed under the "Stage V certified" seal. The particular added value for customers is that switching from the current EU Stage IV to Stage V requires no additional installation space, thus avoiding expensive modifications to customers' equipment. By being the first to obtain EU Stage V certification, DEUTZ says that it is re-affirming its environmental promise and positioning itself as an engine manufacturer with an eco-friendly focus.

From 2019, DEUTZ will also be expanding its portfolio in the higher output range, with four new in-line engines of between 9 and 18 litres capacity. The TCD 9.0 four-cylinder engine and the TCD 12.0 / 13.5 and 18.0 six-cylinder models deliver power output of between 300 and 620 kW and will be aimed in particular at heavy-duty off-highway applications. The models in the TCD 9.0 to 13.5 product range are part of a family platform concept with a standardized customer interface and identical front and rear sides, which make it considerably easier to install and service the engines. The DEUTZ TCD 9.0 has already won two awards: DIESEL magazine named it "DIESEL OF THE YEAR" and it was included among OEM Off-Highway magazine's "Top Ten New Products of 2017."

DEUTZ is extending its product offering in the lower power output range, too. From 2019, based on the successful four-cylinder TCD 2.9 (30 to 75 kW), there will be a three-cylinder variant, the TCD 2.2, ranging in output from 22 to 56 kW. Both these diesel engines will also be available as liquefied petroleum gas (LPG) versions, named G 2.2 and G 2.9. All the variants will be based on the same engine platform, generating extensive synergy effects. These drives will represent a further option, in particular for low-load applications in the material handling and compact construction equipment field.

Get CONNECTED

DEUTZ is also presenting two digital products at Intermat, under the slogan "Get CONNECTED." The free "DEUTZ Connect" service app enables engine diagnosis to be carried out remotely via a Bluetooth-enabled smartphone or tablet. All the relevant engine data and the fault memory can be read out in the field and sent to the dealer with a single click, guaranteeing rapid and precisely targeted servicing procedures. Fleet operators can also use the easy-to-use app to manage their engines and to specify servicing windows, for example. Visitors to the DEUTZ stand at Intermat can put the app to the test on an oversized smartphone.

Visitors can see DEUTZ's new online service portal, another feature of its service provision. Customers anywhere in the world will be able to get in touch with their local service partner to register their engines online and to buy spare parts online 24/7. This platform-based system combines the benefits of the world wide web – unlimited availability round the clock – with the strengths offered by an expert local aftersales service. The provision of aftersales support and parts delivery will remain in the hands of the local DEUTZ partner close to the customer. This allows delivery times to be minimized and the most efficient support to be provided.

Michael Wellenzohn, member of the DEUTZ AG Board of Management for Sales, Service & Marketing: "We are extending our range of products and services in all areas. "DEUTZ Connect" and the new online service portal are examples of how we are investing in digitization in order to save our customers time and money. Our extended, EU Stage V certified engine range will also include E-DEUTZ drive components. We are thus ideally positioned in the market, with innovative drive systems that achieve clear cost savings and environmental benefits."