Komatsu’s largest hydraulic mining excavator arrives in Canada

The PC9000 has been delivered to Suncor’s Fort Hills mine, marking a milestone in ultra-class mining equipment deployment

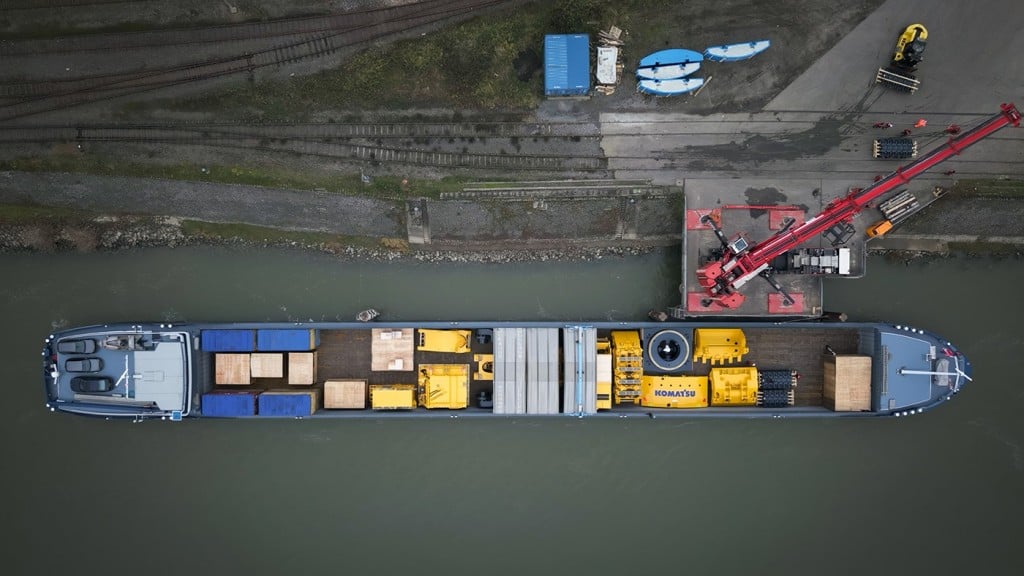

The Komatsu PC9000, the company's largest hydraulic mining excavator, has officially arrived at its final destination. After a highly anticipated international journey from Düsseldorf, Germany, the first PC9000 was unveiled during a special handover ceremony at Suncor's Fort Hills oil sands operation in Alberta, Canada.

Suncor's Fort Hills mine is the first operation worldwide to deploy the PC9000. A second unit is expected to arrive in July 2025, with more machines planned for delivery in 2026.

Komatsu's largest hydraulic mining excavator built for high-production mining

With a total machine weight of approximately 900 tonnes, Komatsu's largest hydraulic mining excavator now stands as the largest hydraulic excavator in Komatsu's portfolio and one of the most substantial hydraulic shovels in the 900-tonne class currently available on the global market.

The Komatsu PC9000 is purpose-built for large-scale efficiency in high-production mining. Engineered as a five-pass match for Komatsu's 980E ultra-class haul trucks, this combination enables fast, double-sided loading to support autonomous haulage systems (AHS) — an increasingly common feature in modern mining operations.

With extended reach, higher digging forces, and an oversized bucket, significantly improving cycle times and lower cost-per-tonne performance — the PC9000 presents operational excellence for mining operations.

Collaboration drives the PC9000's design and innovation

The PC9000 was developed by Komatsu Germany Mining Division (KGM) with direct input from distributors and mining operators.

Canadian distributor SMS Equipment and long-time partner in mining innovation, played a key role in facilitating communication between KGM and field operators. The result is a next-generation hydraulic mining excavator designed to meet real-world productivity demands, featuring stronger digging capabilities and a fully redesigned operator cab.

"This new class of hydraulic mining excavator raises the bar for productivity, efficiency and performance," said Ansgar Thole, president and managing director of Komatsu Germany GmbH, at the handover event. "It stands as the embodiment of an extraordinary partnership between KGM, SMS Equipment, and Suncor."

That partnership spans decades. The three companies previously collaborated to bring several mining firsts to Canada, including the PC7000 front shovel (a model which has since been followed by the electrically powered PC7000-11E), the 980E ultra-class haul truck, and the country's first autonomous haulage systems

Engineered for Canada's oil sands and the Fort Hills mine

The Alberta oil sands present some of the harshest mining conditions in the world, defined by abrasive materials, extreme temperatures, and massive daily production volumes, even for large scale mining operations standards. The PC9000 has been designed with those factors in mind and is built with engineering excellence.

In addition to its digging and loading capabilities, it features a redesigned hydraulic system aimed at reducing energy consumption and emissions, supporting both sustainability goals and operational efficiency.

What comes next for the Komatsu PC9000?

Suncor sees the PC9000 as a strategic investment. "The tangible value the shovel offers to our mining operations made our decision to invest in the PC9000 clear," said Peter Zebedee, Suncor's executive vice-president of oil sands.

With the handover complete, the Komatsu PC9000 is now set to begin operations at one of the largest surface mining sites in North America. Its field performance will be closely monitored by industry stakeholders as expectations run high for this next-generation machine.

Bigger machines, smarter systems

For heavy equipment enthusiasts and mining professionals, the PC9000 represents more than a new model. It marks a shift in where surface mining technology is headed: toward bigger machines, better integration with autonomous systems, and smarter, more collaborative design processes.

As additional units arrive and deployment expands, the industry can expect further updates on how the PC9000 is performing under real-world conditions.