9 tips to prep your wheel loader for winter work

Ready your machines for cold weather with these essential maintenance activities

Wheel loaders are winter workhorses. They lift and carry heavy materials and push and dump snow.

Before winter arrives, prepare your machine so it can take on these tasks with ease. If you equip your wheel loader with winter-ready components to foster operator comfort and safety, you will navigate the harshest winter conditions with ease and efficiency.

Jacob Sherman, product and dealer marketing manager at DEVELON, and Chaise Ireland, president of Conestoga Contracting in Elmira, Ontario, offer a few essential tips to help you get the most out of your wheel loader this winter.

1. Familiarize yourself with the operation manual

First, review the operation manual as early as possible for recommended service intervals, a checklist of seasonal maintenance items, and oil and fluid recommendations. The manual will explain which machine components should be regularly inspected. These include fluids and filters, the battery, tires, grease intervals, and heating and defrosting systems.

"You and your operators should also request training on proper maintenance techniques from your local equipment dealer," Sherman says. "They will help you become familiar with decals and key maintenance points on the machine."

Ireland recommends starting the winterization process in July and completing all repairs by November 1.

"We like to start our process early," Ireland says. "We make a list, order the parts from our local dealer – CG Equipment – and maintain our equipment in our shop. Our fleet team records minor issues, completes periodic equipment checks, and puts the equipment out of service to carry out the repairs instead of losing days of production. They will often perform these inspections on-site to ensure maximum uptime."

2. Change the engine oil

Match wheel loader fluids to the proper ambient temperatures. Harsh temperatures can affect a wheel loader's ability to run efficiently, especially if it does not have the proper engine oil. Using incorrect diesel engine oil can cause costly damage to the machine's internal components.

"These components can become plugged or corroded and not work efficiently," Sherman says. "Make sure to refer to your operation manual for instructions on filling your machine at the recommended intervals with the appropriate fluid in the correct increments."

Most wheel loader manufacturers recommend CJ4 engine oils to protect the machine's vital engine components.

3. Use a winter fuel grade

Switching to a special winter fuel grade, such as No. 1 and No. 2 diesel or a winterized blend, can help you prepare for colder temperatures.

"No. 1 grade diesel fuel has lower energy components than its counterpart, No. 2 grade, because paraffin [a type of wax] has been removed from the chemical mix," Sherman says. "The absence of this chemical allows it to remain in liquid form during winter. The downside of No. 2 diesel is its tendency to transform into a thickened gel when the temperature drops. This can often lead to hard starts and other complications during winter."

Winterized fuel is a combination of No. 1 and No. 2 fuels. When blended, they hold a higher concentration of No. 1 grade fuel and are used when it becomes too cold, starting at 14 degrees Fahrenheit (-10 degree Celsius). The combination of both grades should contain enough energy components and lubricant properties to reduce the chance of the chemical mix gelling in colder temperatures.

"Investing in quality fuel blended appropriately for the climate and season may give you better peace of mind, lower your consumption, provide fewer filter changes, and deliver long component life," Sherman says. "Also, verify the quality of fuel you are getting from your provider, checking to make sure water and other contaminants are not present in your fuel."

4. Inspect diesel exhaust fluid and adjust the coolant

Diesel exhaust fluid (DEF) is another component that is susceptible to variations in hot and cold temperatures. In very cold temperatures, DEF can freeze, so make sure you keep DEF in storage during the winter months.

"Purity and concentration are critical with DEF," Sherman says. "Work with a local dealer to better understand how to store and handle DEF."

Also, inspect the coolant to make sure it's free of impurities as you run the engine. If the coolant needs to be replaced, choose the best grade for your machine and region. For your machine to perform well in colder weather, the antifreeze mix must be properly blended.

5. Check the tires and batteries

Winter maintenance also means checking the tires. Undetected leaks or improper inflation can lead to premature wear and potentially tire failure over time.

"Over-inflated tires reduce surface contact, generally reducing traction," Sherman says. "However, under-inflated tires can result in losing the bead seat and thus create downtime. Therefore, daily checks of tire pressure and tire condition is a good practice."

Using L3 radial tires may be best during winter because they have deeper treads and provide good traction in snowy conditions. Inflating tires with nitrogen gas can be a good alternative to help maintain proper tire pressure.

Before cold weather hits, inspect the wheel loader's battery and charge it if needed. There is always a draw on the battery, so unless the battery has been maintained or disconnected while stored, it will slowly run down and will need to be charged before use.

Batteries should always be fully charged in cold weather. A trickle charger can be connected to help build the voltage at a lower rate, which can improve battery life. It's a good idea to inspect and clean the battery connections. Corroded terminals can cause hard starting and charging issues. You can also use a battery blanket to help keep the battery warm when your machine is not in use.

6. Inspect lights and safety features

Verify that all lights, including headlights and taillights, are functioning accordingly. Replace any burnt-out bulbs to ensure that your operators have the appropriate lighting when working in low light or at night. If you're frequently working at night, consider installing additional lighting on your wheel loader. You can purchase work lights to give yourself extra visibility and make yourself more visible to other machines and vehicles.

"A rotating beacon or flasher is a wise investment to increase operator safety," Sherman says. "Check local requirements to make sure your wheel loader is properly equipped for clearing snow."

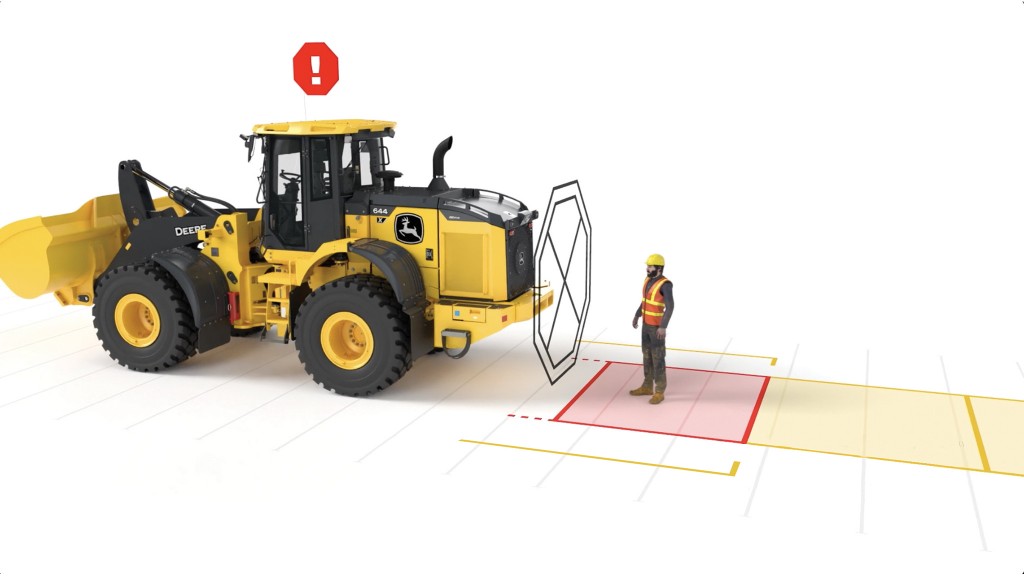

Additionally, inspect advanced safety features such as proximity sensors (object detection), camera systems, and blind spot monitoring, before operating during winter. DEVELON recommends inspecting the Transparent Bucket feature on its machines as well.

Around view monitor (AVM) camera systems are becoming increasingly popular in wheel loaders. These systems use cameras mounted on the machine to provide as much as 270 degrees of visibility to the surrounding area, giving your operators better situational awareness. Some monitoring systems include features such as object detection and warning systems, which sound an alert if there are any potential hazards in the machine's path.

Don't forget to check the cab door and window seals for leaks or cracks, install a new windshield wiper blade, and add low-temperature washer fluid.

7. Inspect attachments

Attachments such as quick couplers, buckets, and snow pushers deserve the same attention as the machine to which they are connected. According to Ireland, his team follows all manufacturer's instructions as well as performing visual checks of attachment components, such as hoses, cylinders, guards, and cutting edges, for damage.

He also follows these practices:

- Add oil spray pre- and post-season.

- Install shrink-wrap in the summer months to slow equipment aging.

- Work closely with a local dealer to ensure that they will have parts in stock at a moment's notice.

- Keep additional snow plows on hand in the event that there is an issue that cannot be fixed quickly. As part of Ireland's strategic planning, his team keeps attachments in certain cities they service so they can swap and go quickly without wasting any time.

- Make sure snow pusher attachments interfacing with a bucket are properly secured with chains as well.

- Maintain three points of contact when entering or exiting the machine, as frozen material can build up during the day, resulting in a slippery surface.

8. Prep for storage

When you are done with your wheel loader for the day, park it in an enclosed, heated facility or out of the wind to protect it from the elements. Storing your wheel loader near where you will be moving snow keeps operations efficient. Many facilities even keep the wheel loader stationed on-site during the snow season.

9. Train your operators

Your equipment is only as good as the people operating them, so make sure to train your equipment operators on proper wheel loader practices and maintenance.

"Cold starting, preventive maintenance, equipment hygiene, and communication are all areas we see other companies failing at, which can result in costly repairs," Ireland says.

According to Ireland, his operators are trained to keep music levels turned down in the cab to hear other machines that are in operation. They also complete a periodic walk-around during the shift to make sure there are no issues with the machine.

"A simple walk-around pre- and post-shift can result in 70 percent of your potential issues being caught before major damage or loss of time occurs," he says. "When a repair or concern is identified, we address it by sending an email to our fleet department. We use special software we created to track and manage the workload along with the manufacturer's fleet management solution."

Ireland also notes that it takes months of planning and training to ensure smooth winter operations.

"We think of all the scenarios ahead of time," he says. "When communicating to our teams in the field, we give them copies of the scope of work for each client's site. If that information is not enough, a direct line of communication by our 2-way radio system lets operators talk directly to dispatch."

By following these tips, you can be better prepared to tackle snow piles and help keep your wheel loader running strong all winter.

Allison Grettenberg is a strategic communications specialist at Two Rivers Marketing.