Vacuworx updates RC Series to increase safety, decrease down time

The lifters now provide real-time diagnostics and enhanced safety features

Vacuworx has updated its flagship line of RC Series Vacuum Lifting Systems. All changes are designed to maximize safety while minimizing down time on the job. In addition, the lifters are "smarter" by incorporating a CAN bus system to provide real-time diagnostics and enhanced safety features.

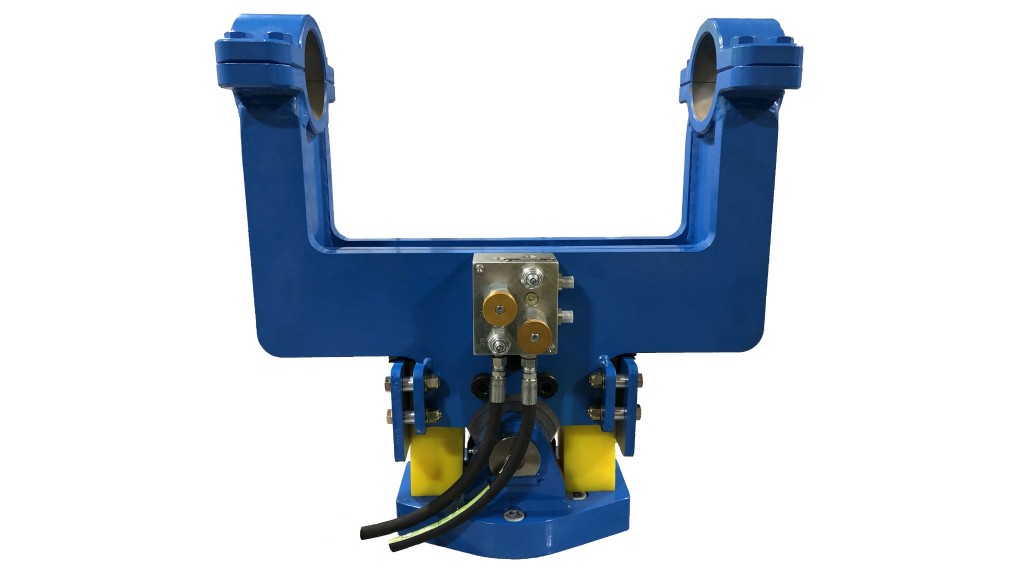

Adapter

The adapter now features removable top caps, which allows the installer to position and secure the adapter pin easily. The standard pin size is 110 mm, but the adapter will also accommodate pin sizes down to 50 mm using bushings. Vacuworx also offers an adapter for 120 mm pins and larger.

A flow control block has been incorporated into the adapter to allow for more safe and convenient adjustment of the hydraulics. This puts the flow controls within easy reach, rather than higher up on the arm of the excavator. In addition, the part of the adapter that connects to the base plate on the lifter, referred to as the "tombstone," is now a replaceable part of the assembly rather than being welded to the adapter. This is designed to minimize time and overall cost of repairs.

Belt drive

The traditional gear box has been replaced with a belt drive. This will provide a longer service life and drastically reduce repairs. There is virtually no maintenance required. The belt drive is environmentally friendly with no oil to replace. In addition, the system design keeps the engine bay temperatures cooler.

CAN Bus System

Vacuworx has implemented an application of CAN bus technology for vacuum lifting systems. Commonly used in passenger vehicles and other equipment, a Controller Area Network (CAN bus) allows internal devices to communicate with each other without a host computer. Utilizing a central logic controller, the system is designed to monitor for faults and quickly diagnose specific problems.

The new dashboard gauge on one side of the lifter shows error codes, oil and fuel levels, pressure level, number of lifts and engine hours. The logic controller increases safety by ensuring that the electronic components are operating correctly.

Virtual circuitry

The simplified wiring design of the system has fewer components and no mechanical switches. The system incorporates pressure transducers instead of a vacuum switch for greater accuracy. All circuits can be monitored and diagnosed through the logic controller. There are no fuses to repair or replace —all faults are reset electronically. In addition, the design helps promote safety by identifying any incorrect repairs or environmental damage.