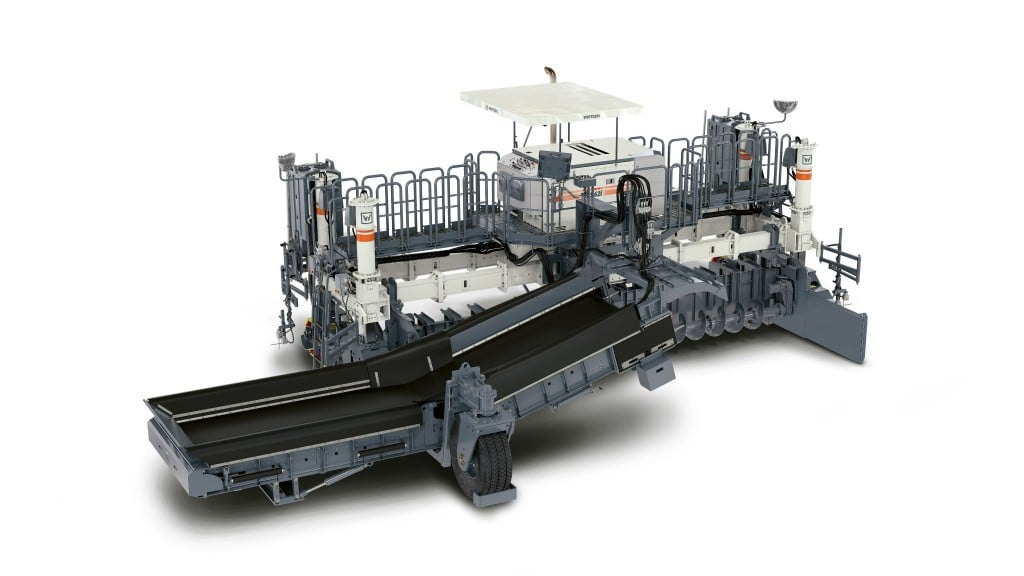

Side-feeding concrete placer/spreader from Wirtgen debuts at World of Concrete

Machine is designed to spread concrete homogeneously in front of the slipform paver

Wirtgen has premiered its WPS 62i/WPS 62 placer/spreader at World of Concrete 2020. It is designed to efficiently feed concrete from the side and spread it homogeneously in front of the slipform paver.

When road surfaces and paths are paved over preplaced reinforcing steel, the concrete can often only be supplied from the side. As the first machine in the Wirtgen paving train, it travels over the reinforcement in front of the slipform paver and texture curing machine. A truck feeds the concrete from the side, which the placer/spreader then evenly distributes over the entire working surface. The WPS 62i/WPS 62 is available with two different scraping units: in imperial units with working widths between 12 feet and 24 feet and in metric units with working widths from 4.00 m to 7.5 m. With both of them, the concrete can be laid up to 20 inches (500 mm) thick.

Thanks to the hydraulically telescoping machine frame and concrete scraper unit, the 2-track placer/spreader can be easily adapted to any job site situation. Its fully modular design with standard hydraulic quick-change couplings means the WPS 62i/WPS 62 can also be easily converted and quickly prepared for transport to the next location.

Operators also benefit from simple, standardized operation of the entire paving train. This is because Wirtgen's development experts have applied the same operating used on the current series of slipform pavers and texture curing machines for the WPS 62i/WPS 62.

Company info

6030 Dana Way

Antioch, TN

US, 37013

Website:

wirtgen-group.com/en-us

Phone number:

615-501-0600