New joystick steering and intelligent assistance systems for Liebherr wheel loaders at bauma 2019

At Bauma 2019, Liebherr presented a comprehensive range of intelligent assistance systems for selected wheel loaders from the corporate group. These include, for example, active rear person recognition, front area monitoring and the Skyview 360° camera system. These solutions increase safety and reduce the burden on the machine operator, whose everyday work with the wheel loader brings with it a significant weight of responsibility. Another assistance system is the new weighing device, which functions as a control scale over a large lifting range. All the new assistance systems have been developed by Liebherr and are therefore fully integrated into the machine control. This also applies to the new joystick steering for models from the L 526 to the L 586 XPower. The intuitive operation of the joystick enables the operator to steer accurately and without fatigue, as its position always corresponds to the wheel loader's current articulation angle.

From the compact L 506 wheel loader to the largest model, the L 586 XPower, Liebherr presented a cross section of all wheel loader size classes at bauma 2019. These include three power-split XPower large wheel loaders with a variety of intelligent assistance systems. The first of these is an L 550 XPower, which demonstrated a number of new assistance systems several times a day in a live show at the Liebherr stand. The second is an L 580 XPower equipped with assistance systems and a 13 m³ high-dump bucket for industrial use. The third wheel loader is an L 586 XPower weighing over 32 tonnes with new joystick steering and an operator's cab without a steering wheel.

New joystick steering with force feedback and position control

The new joystick steering is an innovative steering system available as an option for wheel loader models from the L 526 to the L 586 XPower. It enables the operator to steer comfortably with one hand. Particularly where the work involves numerous steering maneuvers, the joystick steering system saves energy and makes the work less physically strenuous as short movements on the ergonomically shaped joystick replace cranking of the steering wheel. The left arm stays comfortably on the armrest and because the travel direction can be changed with a switch on the control element, the left hand remains on the joystick even when changing direction.

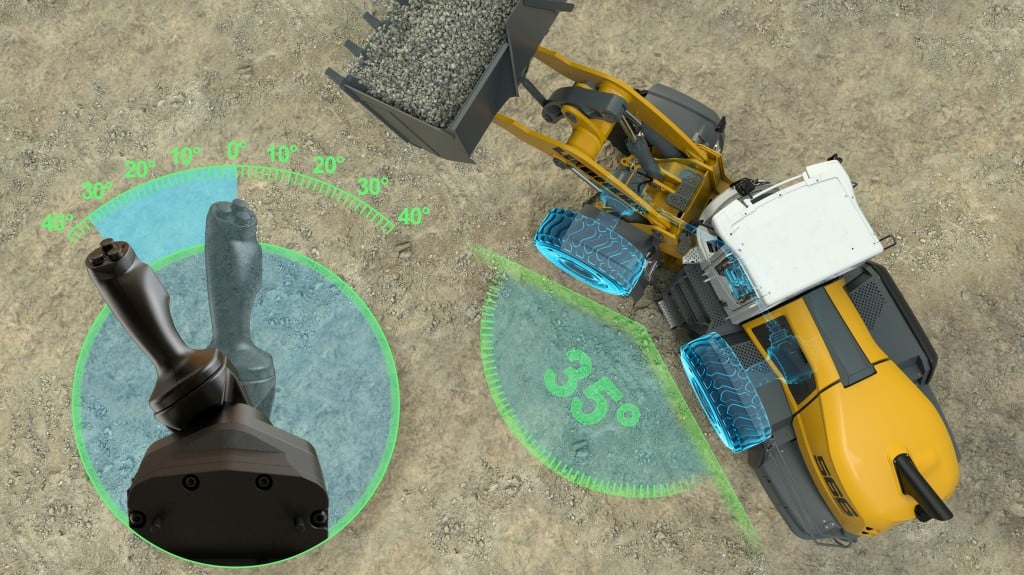

Operation of the new joystick steering system for Liebherr wheel loaders is intuitive. One reason for this is that the position of the joystick always corresponds to the respective articulation angle of the wheel loader. Together with the force feedback on the joystick, the new steering sets the standard in terms of user-friendliness, providing an impressive alternative to conventional joystick steering systems. The operation of Liebherr wheel loaders with new joystick steering is therefore safe and comfortable, even at high speeds and in difficult terrain.

As well as having the option of joystick steering, the L 566 XPower to L 586 XPower models are available with an operator's cab without a steering wheel and steering column. In this version, the XPower wheel loader's spacious cabin offers even more room for the driver along with an optimized view of the working attachment.

New weighing device with automatic adjustment of weighing range

The extensive range of intelligent assistance systems includes the new weighing device for XPower large wheel loaders. This solution, developed by Liebherr, is a control scale that works automatically and provides the machine operator with valuable information on the loading operation. It helps the operator to accurately load trucks or dumpers with the right amount of material and avoid overloading. The advantage is that, depending on the application, the ideal weighing range is set automatically and the weighing takes place during the regular loading cycle. This means that the operator does not have to reach a specific lifting height to correctly weigh the bucket contents.

A special feature of the new Liebherr weighing device for wheel loaders is Truck Payload Assist. This innovative system supports material handling with a wheel loader in a number of ways. For example, the operator can enter a target loading weight on the display. Using this information, the Truck Payload Assist calculates the optimal target weight to be loaded per bucket and the required number of loading cycles. The result is higher productivity through consistent, accurate and machine-friendly loading of lorries and dumpers. And time-consuming, but often necessary, shaking or re-weighing of bulk material in the last bucket is eliminated.

The machine operator can easily view all weighing data and the Truck Payload Assist recommendations on the display and in real time. A sophisticated colour concept helps the operator to increase the user-friendliness of the weighing device. In addition, the operator can evaluate the weighing data via the Liebherr LiDAT data transmission system in order to analyse their production process or the productivity of their wheel loader fleet.

Enhanced safety with front area monitoring and Skyview 360°

In industrial applications, Liebherr wheel loaders often work with large attachments, high-dump buckets for example, when handling lighter goods such as wood chips, paper or waste. Because large buckets inevitably obstruct the driver's field of vision, Liebherr offers L 526 to L 586 XPower wheel loaders with a roof camera for front area monitoring. The roof camera provides a view of the bucket in front of the machine from a significantly elevated perspective and transmits the image on a separate display in the operator's cab. Front area monitoring is therefore used for seeing people or objects hidden by the attachment, which increases safety when accelerating, driving forward and loading with large buckets.

The Skyview 360° camera system is another intelligent assistance system that enables the machine operator to recognise potential hazards. As four additional cameras capture the machine's entire surroundings, it provides a 360° view of the wheel loader's immediate vicinity at all times. The system merges the individual images into a virtual bird's-eye view and shows this image on a separate display in the operator's cab. With this perspective, the operator can effortlessly see blind spots and danger zones, such as the wheel loader's articulation area, and avoid possible collisions.

Company info

1015 Sutton Drive

Burlington, ON

CA, L7L 5Z8

Website:

liebherr.com/en/can/about-liebherr/liebherr-worldwide/canada/liebherr-in-canada.html