CDE launches new tech solutions to help customers achieve maximum plant efficiency

CDE CORE uses automation and sensors to monitor and enhance productivity

Wet processing equipment manufacturer CDE is launching an innovative new range of technology solutions to enable customers to increase the efficiency of their plant, automate processes, and lower their operating costs.

The benefits will be outlined to the market at a masterclass entitled ‘The Connected Plant' at CDE's stand on the Wednesday 10th April at Bauma. (Stand Number: FN 1022/1, Outdoor Exhibition Area, North/East)

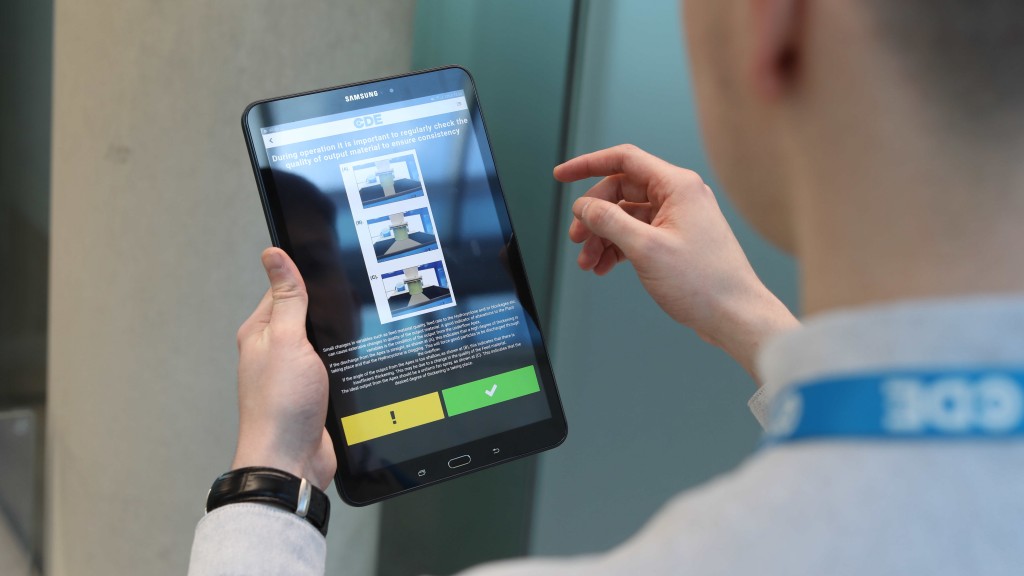

The CDE CORE smart technology suite includes three key features: an easy-to-use monitoring system; a digital tool to manage and simplify operator workflows; and a bespoke 3D catalogue of parts which is tailored for each customer's individual equipment.

It gives customers greater control of their plant, and means, among other things, that resources are being maximized and customers can take immediate action if the efficiency of their plant falls below their desired level.

Tom Houston, Director of Custom Care at CDE, said: "CDE CORE is designed to reduce operating costs and give our customers the best return on the investment they have made in a CDE plant. It uses the latest technology, with a simple to use interface, and we believe it will enhance CDE's reputation of being the disrupters and innovators in the wet processing industry. For customers, it is about having a connected plant that gives them greater control, enhanced operational efficiency, better resource and asset management, and increased ease of operation."

"CDE CORE has been in testing on a number of our sites for up to a year and customers have been very impressed with the rise in productivity and the reduction in operating costs brought about by the introduction of automation. More of our customers will now be able to derive these crucial benefits through solutions that are fully-supported by our CustomCare team," Mr Houston adds.

The CDE CORE smart technology suite is part of CDE's CustomCare offering, which includes a dedicated team of regional service engineers who are proficient in the commissioning and ongoing maintenance and optimization of CDE equipment.