Three new products introduced by Multiquip at World of Concrete

Multiquip has introduced an all-new backpack concrete vibrator motor, an updated MQ Essick 12 cubic foot towable mixer and a state-of-the-art chemical spray system at the 2017 World of Concrete in Las Vegas.

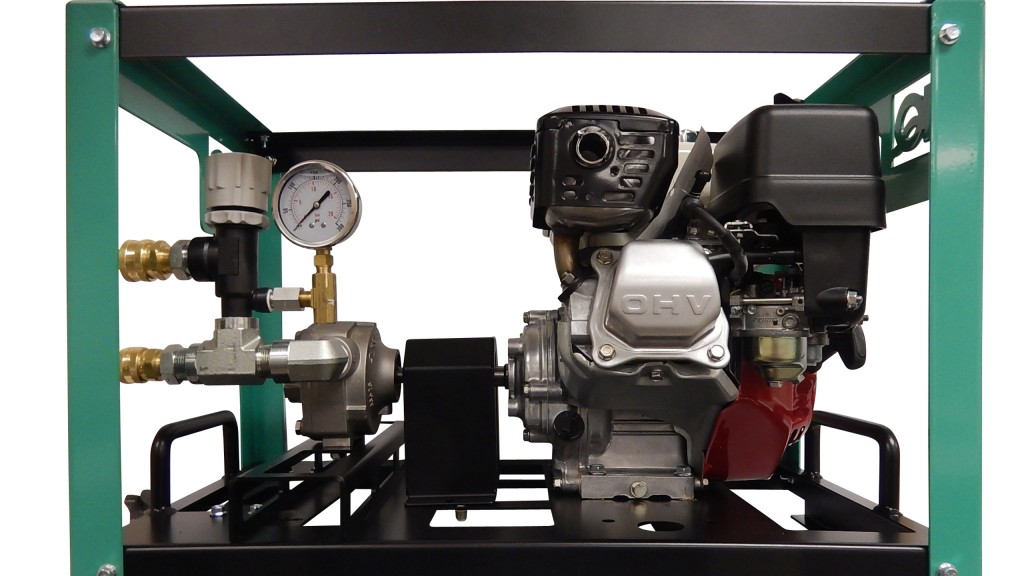

MQ Whiteman Chemical Sprayers are versatile and innovative products that provide exceptional value and performance for concrete flatwork contractors. A cart mounted system, model WSC55, which features an onboard compressor that enables the contractor to clear the lines. The ability to clear the lines enables the solutions to be reused, reducing product waste and creating savings in the process. The versatile cart handles material in drums up to 55 gallons or up to four five-gallon buckets, and features a sloped platform to facilitate spraying. A hose rack accommodates up to 150 feet of hose. The WSC55 is transported easily around the job with its steerable, smooth tire design.

A barrel mounted system, the WSC55BM is also available. Its compact design can be conveniently mounted on top of a barrel or utilized as needed by the contractor. Both models are powered by a 5.5 HP Honda gasoline engine and feature a pump with a capacity of 18 GPM.

The BPX strengthens Multiquip’s already solid line up of flexible shaft concrete vibrators. Weighing only 31 pounds, the BPX is ideal for applications such as masonry block fill, footings and slab on grade pours. The ergonomic frame provides multiple adjustments to reduce operator fatigue and features breathable materials for enhanced comfort.

Power is provided by a reliable Honda 2.1 HP gasoline engine that provides easy starting and proven reliability. Throttle control and start/stop functions are located on the shoulder straps for convenience. The BPX is fully interchangeable with Multiquip’s flexible shaft line.

The model EM12M is the flagship of the MQ Essick mixer lineup and incorporates several new features to improve productivity and ease of operation. The redesigned heavy-duty steel tub reduces material waste from paddle splash. A rugged, rectangular T-frame design enables operators to discharge material easily into wheelbarrows and includes a forklift pocket to simplify job site handling. A new vertical lock automatically secures the tub when returned to the upright position for safety. Also, for the first time, rear stabilizers are available as options for high-production applications.

The Honda engine is upgraded to the more powerful GX390 for better performance when mixing low slump mix designs. The engine is protected by a new one-piece, 12 gauge steel engine cowling that swings open to provide complete access to the drive system for maintenance. Smooth towing on the job and over the highway is assured by U-type spring suspension.