Major FLEX-MAT

Manufacturer

| Address | 225 North Montcalm Blvd., Candiac, QC, J5R 3L6, CA |

| Phone | 450-659-7681 |

| Website | majorflexmat.com/en |

| Follow Us |

About:

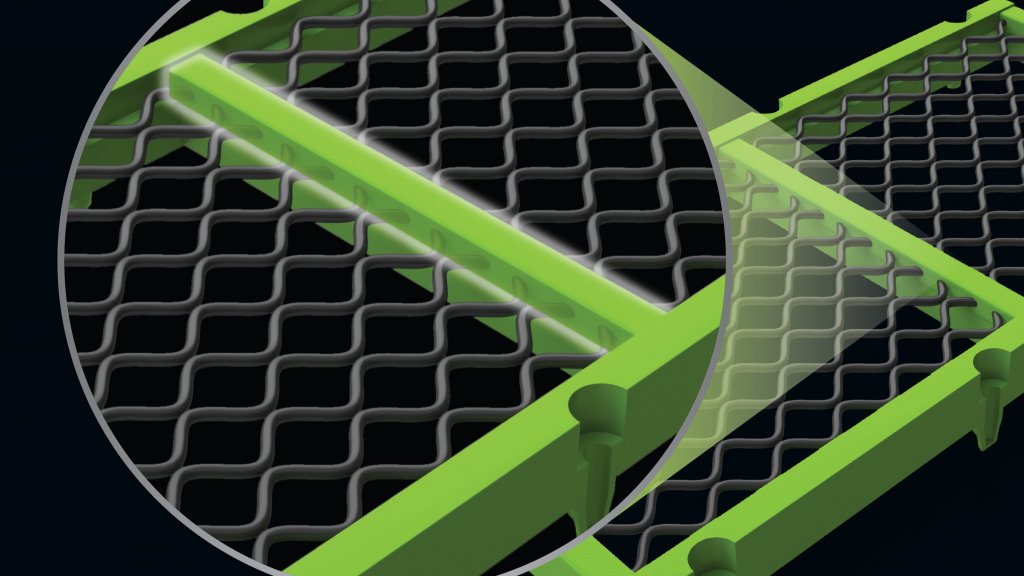

MAJOR is a leading global screen media (screen cloth) manufacturer. Our knowledgeable and experienced Authorized Dealers are dedicated to helping customers in the aggregate, mining, recycle, asphalt, slag, green waste, top soil and other related markets achieve maximum screening performance. Our innovative offering includes FLEX-MAT® High Vibration Wire Screen Media in Tensioned and Modular versions and Woven Screen made with FLEX-MAT's OptimumWire®.

For decades, we have engineered and produced high-performance screen media that:

• Increases screen capacity and throughput.

• Virtually eliminates blinding, pegging, and clogging.

• Provides up to 3-4 times more wear life than the competition.

• Reduces annual screen media expenditures while increasing tons per hour.

Our unique customer support package includes:

• Results Guaranteed Program: eliminates any risk for new customers and/or new applications with existing customers for our FLEX-MAT products.

• Screen Maintenance Seminars: educate customers on screening techniques, troubleshooting and how to maximize wear life.

• On-site Screening Performance Assessments: help customers identify production issues, evaluate their impact and provide a formal report complete with photographs and straightforward recommendations.