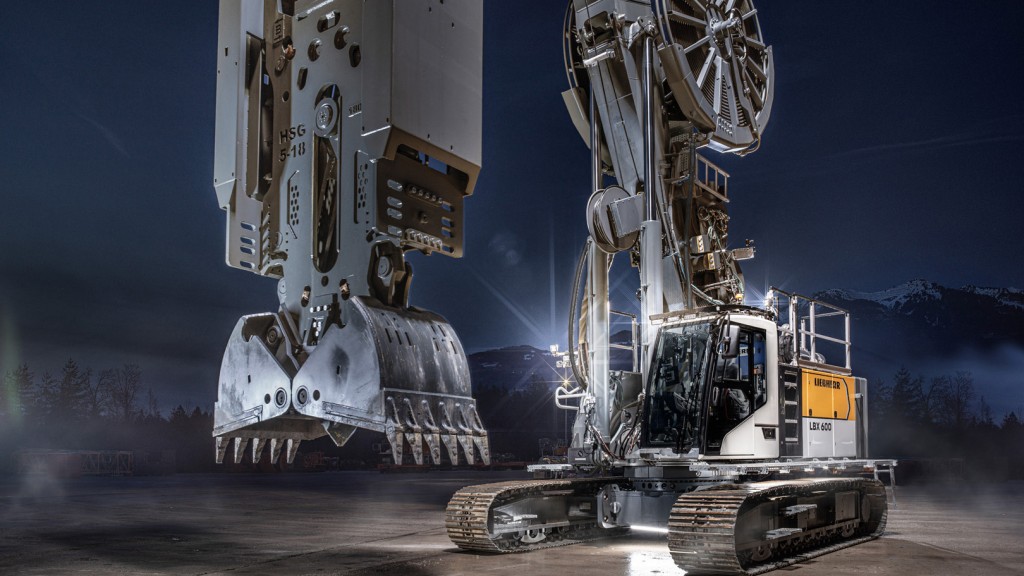

Liebherr carrier machine for slurry wall construction fits compact urban job sites

The compact Liebherr LBX 600 carrier machine for slurry wall construction is designed for job sites in urban areas. Its small size combines with the unplugged version to allow for work in confined spaces and noise-sensitive areas.

Standard height of the LBX 600 is 17.8 metres, but its modular design allows for the use of a 11-metre Low Head boom or the Ultra Low Head boom at just 5.8 metres when work must be done in sites with overhead challenges. In addition, the slim design of the machine and a telescoping undercarriage make the machine easier to transport with a reduced width of 3 metres.

The LBX 600 carrier machine is designed for work with a hydraulic grab and also with a mechanical grab or chisel, thanks to two free-fall winches with a line pull of 300 kN each. In combination with the HSG 5-18 hydraulic slurry wall grab, the LBX 600 offers intuitive operation, enabling hydraulic corrections to the grab alignment and higher verticality of the trench. Available grabs include the HSG 5-18 C and HSG 5-18 L; the C version is a compact design for the low head version, while the base body of the L is 2.5 metres longer. The resulting height of the grab, at 9.5 metres, and the high weight with low centre of gravity, provide for even better vertical positioning and are especially advantageous when installing slurry walls with larger dimensions.

The slurry wall grab is fitted with a hydraulic rotating device, which allows the grab to be aligned in all directions and provides for quick and operator-friendly 180-degree rotation after each grab cycle. A fill level indicator on the grab ensures high productivity throughout the entire application.

The LBX 600 is available in both conventional and battery-powered versions. The unplugged version has identical performance data to the standard version, but produces zero emissions and far lower noise, making it a good fit for noise-sensitive areas. The battery is charged using a conventional job site electrical supply, and the machine can continue to run as normal while the battery is charging.

The PDE process data recording system can record and visualize all working processes for slurry wall construction. Operated and displayed on a touchscreen in the cabin, PDE records operating data from the machine's Litronic control system and data from external sensors.

Users can work with MyJobsite software to record, display, analyze, and manage all relevant machine and job site data in a central location. Collected data is accessed via a web browser. Users can generate reports on proof of quality immediately after work is complete, saving time.

In addition, the LIDAT data transmission and positioning system provides information about location and operation of the machine for improved fleet management.

Learn more about the LBX 600

Company info

1015 Sutton Drive

Burlington, ON

CA, L7L 5Z8

Website:

liebherr.com/en/can/about-liebherr/liebherr-worldwide/canada/liebherr-in-canada.html