Cummins' most efficient heavy-duty diesel engine will meet 2027 emissions regulations

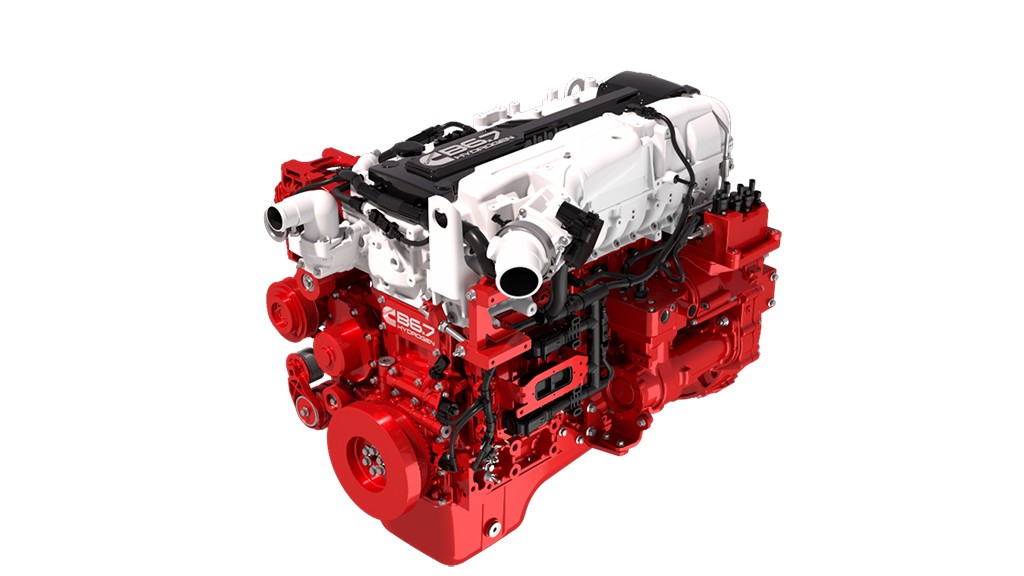

Cummins has announced plans for its most efficient heavy-duty diesel engine ever, to be introduced as part of the 15-litre fuel agnostic platform.

The company is also reintroducing the fuel agnostic platform under the name Cummins HELM, designating engines that have higher efficiency, lower emissions, and multiple fuels. The new X15 diesel is being developed for the heavy-duty on-highway market to comply with U.S. EPA and CARB 2027 regulations at launch.

The next generation X15 will feature improved greenhouse gas and fuel efficiency benefits while retaining the same ratings as the current X15, up to 605 horsepower and 2,050 ft.-lb. of torque. It will also take advantage of optimized powertrain integration with Eaton Cummins and Cummins-Meritor.

"Today, we re-introduce our fuel agnostic engine platforms with a name that captures the innovation that powers us forward: the Cummins HELM platforms," said Jane Beaman, Vice President Global, On-Highway Business, Cummins. "With higher efficiency, lower emissions, and multiple fuels, the Cummins HELM platforms give our customers control of how they navigate their own journeys as part of the energy transition. They can choose the fuel types that work best for them, their businesses, and their goals."

The HELM platform features a series of engine versions derived from a common base engine, which provides parts commonality Below the head gasket, engines will largely have similar components, while above the gasket different components will be in place for different fuel types. Each engine version will operate using a different, single fuel. The X15N, the natural gas variant, is the first engine available to customers. Cummins HELM platforms include the B, X10, and X15 engine platforms.

The X15 diesel is capable of using biodiesel blends up to 20 percent and renewable diesel blends up to 100 percent.

The next-generation X15 diesel was developed with Cummins' fully integrated powertrain in mind. The architecture uses a belt-driven, high-output 48-volt alternator and aftertreatment heater solution, optimized for increasing emission standards.

Eaton Cummins Endurant HD and XD series transmissions are optimized with the next generation X15 powertrain to work seamlessly, improving efficiency and performance while maintaining drive comfort. Transmission lube change intervals are up to 750,000 miles. Remote diagnostic capabilities are available.

Cummins-Meritor 14X HE tandem drive axles are designed for performance, durability, and fuel economy. They are equipped with an advanced Meritor lube management system and feature super-fast ratio options, fuel-efficient bearings, and high-efficiency spiral bevel gearing. Permalube RPL drivelines are designed for reduced maintenance and can handle high torque demands.

As part of its commitment to internal combustion engine innovation, Cummins is also focused on digital products and services to enhance Cummins engines throughout their lives. This includes securely connecting real-time data from vehicles on the road to maintenance and service operations. The new X15 is equipped with Acumen, which provides digital connectivity and direct, immediate access to a range of applications and capabilities that provide value throughout the engine's life cycle.