Terex Utilities has released a video demonstrating the importance of selecting the right auger tool for the job conditions. Selection factors include auger style tools or barrel tools, various types of teeth, and multiple tool sizes.

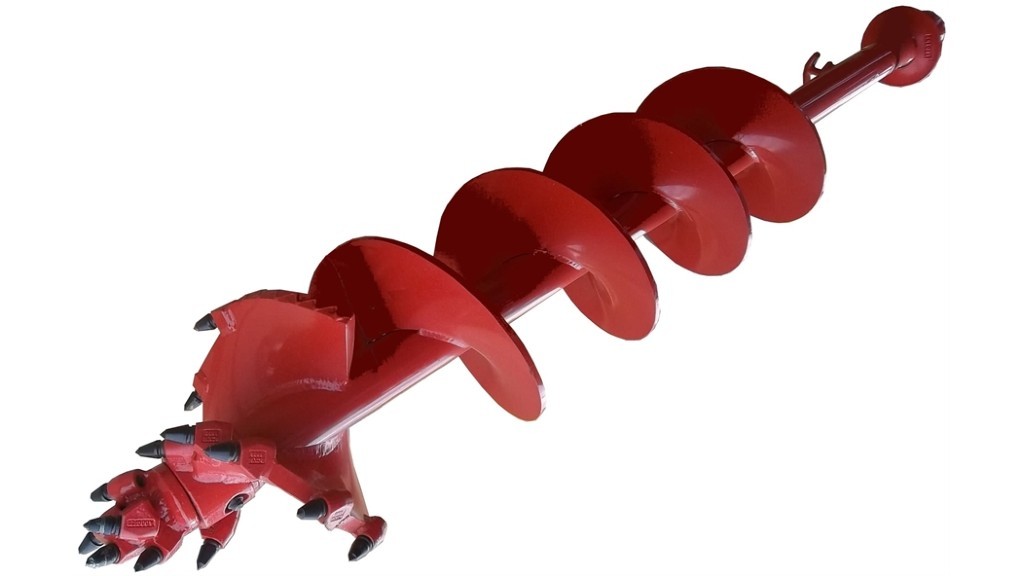

In the video, Terex Utilities performs a side-by-side comparison of its TXC Auger and BTA Spiral with carbide bullet teeth drilling into the concrete. The TXC is best for loose, compacted soils; stiff clays, shale, cobbles, and medium rock strata. It's not designed for cutting through concrete or hard rock. In contrast, the BTA Spiral is efficient for drilling into hard rock and concrete. After about 12 minutes, there is a drastic contrast in the amount of work accomplished by the BTA Spiral

"Be sure to match the tool with the ground conditions. Most tool specifications will include a description of the type of applications for which the auger tool or barrel is designed. In addition, the type of teeth on the pilot bit is directly related to the application it's designed to work in," said Greg Adler, Regional Account Manager for Auger Tooling. He also recommends that the pilot bit and flighting teeth are compatible, with the same strength and cutting characteristics.

"Augers have flights to lift the spoils that are loosened by the teeth and a pilot bit that stabilizes the drilling process for a straight hole, while core barrels cut a single track applying more pressure per tooth, removing rock materials by lifting out the material as individual plugs," said Dale Putman, Product Support Manager. The second demonstration in the video is of the Terex Stand Alone Core Barrel, shows just that process in action.

To see the side-by-side video comparing the TXC Auger and BTA Spiral, watch here.