The electric-drive GS-1330m scissor lift features low noise, low emission, low weight and low floor loading capabilities, and now, when equipped with the Genie Lift Tools Spill Guard accessory, it increases its already low environmental impact. The new Genie Lift Tools Spill Guard system is engineered to contain hydraulic leaks, preventing costly cleanup, as well as reducing the scissor lift's total cost of ownership (TCO) and maintenance requirements by eliminating the installation and removal challenges associated with conventional hydraulic diapers. This new optional accessory can be ordered from the factory on new production units or as an aftermarket kit to retrofit units already in the field.

"Hydraulic containment is an increasing focus on jobsites globally, particularly in the ‘micro' scissor category class of scissor lifts," says Michael Flanagan, Genie Product Manager, Terex AWP. "Today's jobsites want efficient machines, and although hydraulic leaks are rare on electrically driven machines, such as the Genie GS-1330m scissor lift, some jobsites will mandate hydraulic or leak containment solutions as an added layer of prevention. This is increasingly becoming a requirement on data farm jobsites focused on maintaining ‘clean' jobsites, as well as slab buildings, where the concrete slab will be the finished floor — because if there is a hydraulic leak, it will show through the finish. The Genie Lift Tools Spill Guard prevents a small leak from becoming a big concrete repair bill."

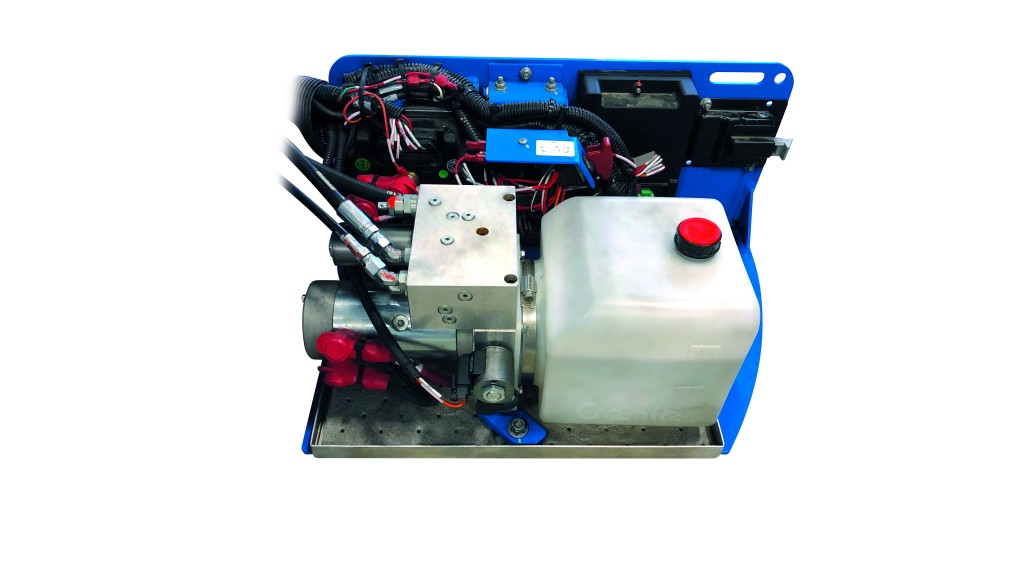

Easy to install in the field, the new Genie Lift Tools Spill Guard accessory can be upfitted to any Genie GS-1330m scissor lift in less than 30 minutes. Following the initial installation, the absorbent pad takes less than five minutes to replace. "This is an improvement over traditional hydraulic diapers, which can take more than 20 minutes to install each time, and often get torn on jobsites, eliminating the capability to actually contain leaks," says Flanagan. According to Flanagan, the absorbent pads installed with the Genie Lift Tools Spill Guard are similar to hydraulic diapers and are engineered to contain hydraulic leaks under the hydraulic power unit and steer cylinder.

Focused on maximizing uptime, the new Genie Lift Tools Spill Guard system is also simple and easy to service: Simply open the tray to check for leaks; no need to completely replace an expensive diaper. "Keeping our customers' TCO top of mind, we designed the new Genie Lift Tools Spill Guard to increase productivity and improve serviceability, saving time and money."