When it comes to the precision and cost-efficient construction of concrete pavements, Wirtgen's slipform pavers are right for the job. With their modular design, the machines can be configured as needed, and virtually all conceivable structures are possible, including special shapes.

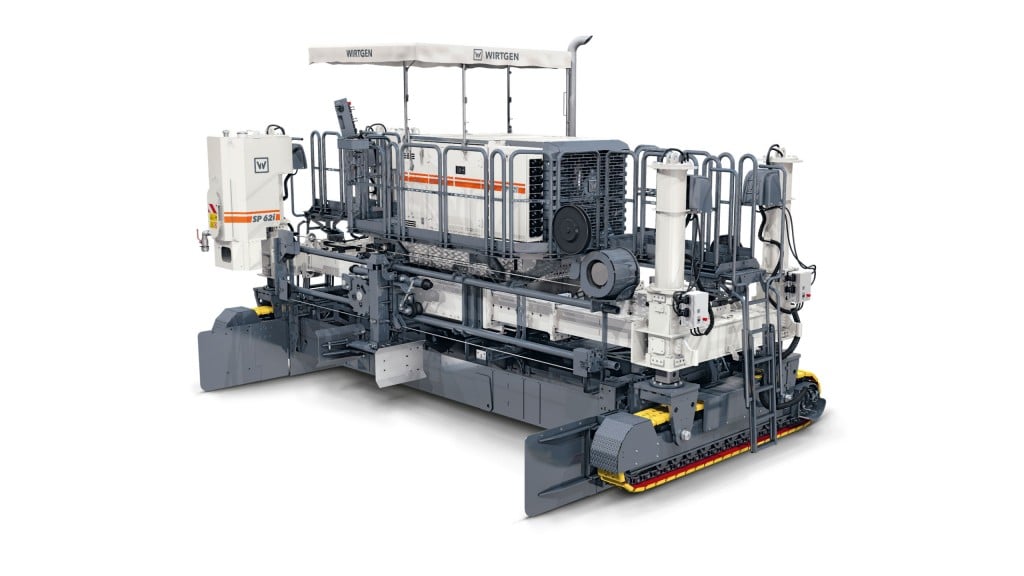

Thanks to its versatility in inset and offset applications, the SP 60 series is the new multi-talent for concrete paving. With its SP 61i, SP 62i and SP 64i models, Wirtgen has developed a new series of slipform pavers that delivers the diverse applications of the globally successful SP 500, while the SP 62i adds a two-crawler machine to the lineup. With a paving width ranging up to 25 ft. (7.62 m), the SP 62i is a particularly cost-effective option for customers wishing to enter the mid-range inset paver business.

The SP 62i can precisely pave concrete in widths from 6 ft., 6 in. to 25 ft. (2.00 m to 7.62 m) and thicknesses of up to 18 in. (450 mm) - or more upon customer request. The intelligent steering and control system ensures extremely smooth operation even around tight corners. Thanks to the simple modification and extendability with additional options, the SP 62i can be quickly set up and adapted to any job-site situation. Due to its easy transportability, the paver is quickly available on-site.

As part of its modification measures to comply with new emissions laws, Wirtgen has designed the SP 62i for a greater engine output. Meeting EU Stage 4 and US Tier 4 Final emissions specifications, the machine has a 180 kW Deutz engine. Despite the higher output, fuel consumption is sustainably reduced by the Eco Mode, which automatically adapts engine output to power requirements.

More features than ever operate hydraulically. Thanks to a new hydraulic concept, energy is now used more efficiently, meaning it is available for new equipment options. Among other things and depending on customer requirements, the paver can be equipped with a hydraulic vibrator drive. In standard design, it comes with 12 hydraulic connectors but can optionally be fitted with 18 connectors. Another example: the separate hydraulic side bar inserters, which can be mounted on the left, on the right, or on both sides of the machine.

The hydraulic system starts as a basic version, and grows along with the number of modular equipment options selected. For customers, choosing options to meet their needs is highly cost-efficient.

The machine control system in Wirtgen's slipform pavers is likewise state-of-the-art. Interfaces for the Wirtgen Group's WIDIAG service diagnosis and WITOS FleetView systems support users.

The two crawler units of the SP 62i run in opposite directions at the push of a button so that the slipform paver turns on its own axis for maximum maneuverability.

Meanwhile, the two long crawlers with their larger footprints also exert a low pressure on the ground. This enables the machine to be used on difficult terrain and improves the cost-efficiency of the paving results.

With the new SP 60 series, Wirtgen has not only expanded the variety of applications in its class of machines for paving widths of up to 25 ft. (7.62 m) (inset paving) and increased the range of offset applications, but by introducing the SP 61i, SP 62i and SP 64i, it has also extended its line of slipform pavers to 12 models.

The SP 60 series therefore rounds out the high end of the offset line, comprising the SP 15i and SP 25i. In terms of inset pavers, it bridges the gap between the small and the mid-range models in the SP 90 series, with paving widths up to a maximum of 31 ft., 2 in. (9.5 m). The large inset slipform pavers with a maximum paving width of 52 ft., 6 in. (16 m) complete this product family.

Company info

6030 Dana Way

Antioch, TN

US, 37013

Website:

wirtgen-group.com/en-us

Phone number:

615-501-0600