Meeting schedules, staying on budget, and following design plans are the core principles for companies performing earthwork operations. Having a balance between these three responsibilities is a difficult task and requires the right combination of technologies to be successful. An enterprise aerial intelligence platform with purpose built earthwork analysis tools is giving construction and engineering companies the power to control the success of a project.

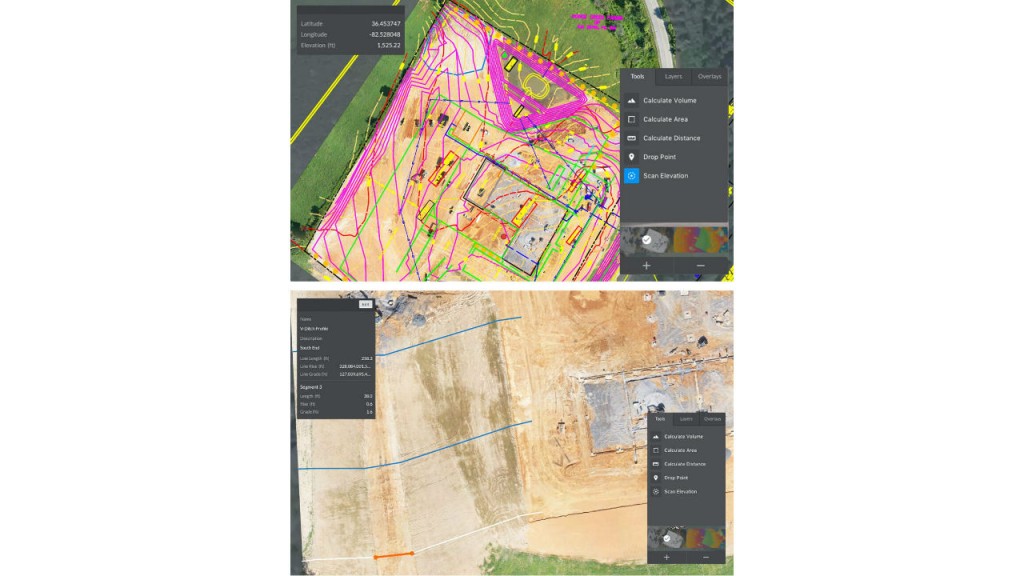

Kespry is bringing that complete solution to earthwork contractors - a fully autonomous drone capable of achieving 2 cm positional accuracy and online software (Kespry Cloud) offering CAD-like functionality. But it's what's inside the Kespry Cloud that has construction and engineering companies taking a harder look at aerial intelligence. With the new Earthwork Toolset, everyone involved on various phases of the project has the ability to perform quick analysis or validation with confidence.

The capabilities of these tools are taking the industry well beyond simple topographic maps. It has opened up much more opportunity to gain insights on project sites before construction begins and all the way through the as-built phase. Kespry's Earthwork Toolset is providing an efficient and accurate solution for bidding, planning and managing earthwork operations.

Tools for Bidding and Planning

When contractors decide to bid a job, they rely on the accuracy of design plans to perform takeoff calculations. If you don't bid the job correctly you're likely to have some sort of fallout like unexpected rework costs. Or if there is a mistake in the plans it's usually found once the job has begun, which is often too late.

Validating existing surface site conditions before bidding is critical to prevent this situation. Construction companies are faced with a challenge of how to quickly obtain accurate survey information on large projects using traditional survey methods. This is where an aerial intelligence solution like Kespry comes into play with its new Earthwork Tools.

Vectorized PDF Overlay - Allows construction and engineering customers to quickly import design plans into the project site.

3D Polyline - Provides customers the ability to calculate the changes in slopes across any surface.

Scan Elevation - At any location on a site, customers are able to verify the coordinates and elevation of any point.

Once operations are in full swing on a project, obtaining regular updates on the earthwork progress and phase completion is critical. The sites are moving so fast that miscounts in haul trucks or misinterpreted grade checks can cause companies to move more material than originally planned.

The issue arises because of a lack of data - both in frequency and accuracy. It's not only the time spent in the field collecting the data that often causes jobs to shut down, but also data turnaround time.

The new Kespry Earthwork Tools along with the scaleable Kespry 2s drone gives companies a complete package to "deploy on demand" during ongoing operations.

Surface Comparison - Allows customers to measure the cut and fill changes between two flights across the entire site or within a designated region.

Base Plane Visualization - When measuring cut and fill volumes, customers are able to verify the accuracy of how the material was calculated in a 3D environment.

Cut and Fill Report - Provides customers an automatically generated report showing the cut and fill differences between the two compared surfaces.

The new Earthworks Tools are empowering construction and engineering companies to drive the success of their projects using aerial intelligence. The frequency and accuracy of data obtained from deploying a Kespry Drone system within an active construction site is a huge advantage, while leveraging CAD-like tools in a online software environment makes cut and fill analysis simple and accessible.