Lift-off: Genie launches dual-envelope Xtra Capacity boom lift to handle heavy loads while meeting new safety standards

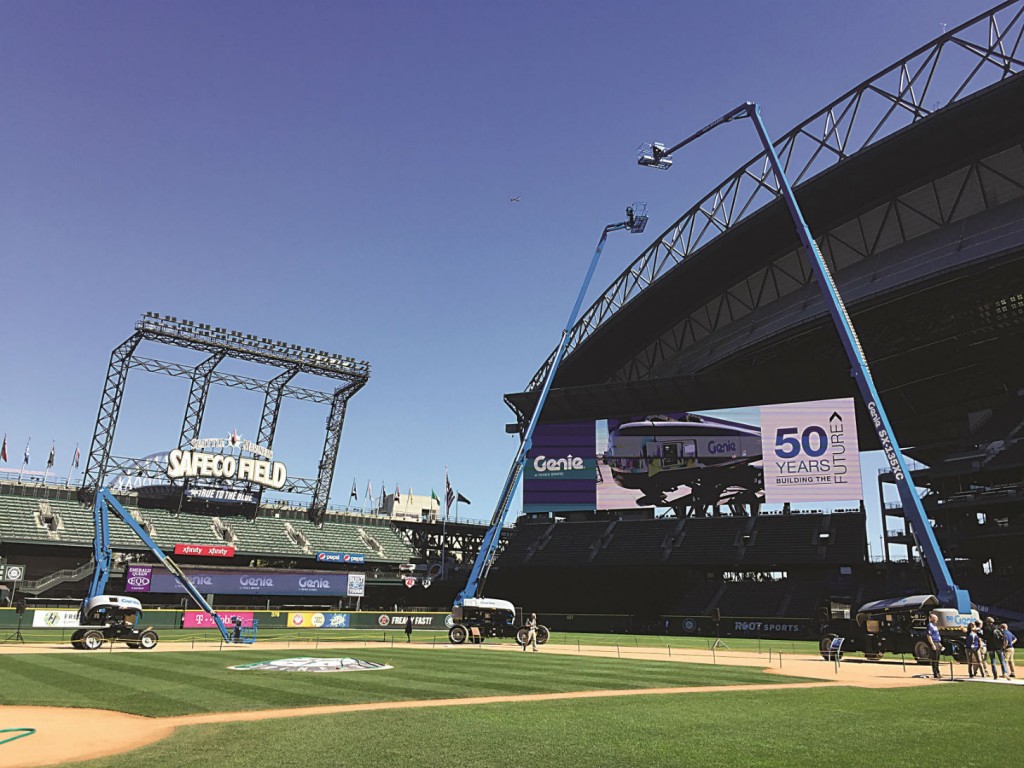

For its 50th Anniversary, Genie is not merely content to sip champagne. The company has popped the cork on a new innovation, the first in a new line of Xtra Capacity boom lifts. Genie has been marking its anniversary throughout 2016 with customer and employee appreciation events and those celebrations culminated on September 14 with Genie’s 50th Anniversary celebration held in Seattle, Washington. More than 300 customers from 47 countries had the opportunity to tour Genie facilities in nearby Redmond, check out new equipment and celebrate the company’s legacy.

Genie SX-135XC boom lift

On Safeco Field, home of the Seattle Mariners, Genie displayed an impressive array of their equipment including the debut of the Genie SX- 135XC boom lift – the first model in their new family of Xtra Capacity (XC) Genie boom lifts.

The Genie SX-135XC boom features 27.43 m of outreach, 300 kg of unrestricted lift capacity, the ability to work 6 m below grade and a 3.94- x 4.11-m compact footprint.

“With 3 m more outreach and 32 percent more capacity than typical self-propelled booms of this size, the Genie SX-135XC boom lift is ideal for rental customers working on challenging jobsite applications with its unique up-and-over style capability to navigate obstacles at height,” said Adam Hailey, Genie Director of Product Management, Terex AWP.

The SX-135XC is built to safely and quickly lift operators to full platform height – 41.15 m – in 2-1/2 minutes, and drive enabled at full height. It has a 74-hp (55-kW) Deutz TD2.9 L4 Tier 4 diesel engine with four-wheel drive and four-wheel steer capabilities.

The boom’s innovative design includes a working envelope with a working height of 43.15 m and a horizontal reach of 27.43 m. According to Genie, that’s 3 m more outreach than any other self-propelled boom on the market.

The SX-135XC has a 5.48- to 9.14- m Telescoping Jib-Extend jib for up-and- over capabilities, as well as 125 degrees of vertical jib articulation – 55 degrees down to 70 degrees up. The working envelope is also increased with this boom’s extended reach out and down capability – 6 m of reach below grade.

“To accommodate the Genie SX- 135XC boom lift’s increased capacity and range of motion, Genie engineers developed a new hydraulically Telescoping Jib-Extend design that is robust enough to handle all of the up, over, out and below tasks rental customers need to do. And when the job is done, the jib is designed to be stowed under the primary boom for ease of transport,” said Hailey.

This boom features the new Genie mini XChassis axle design, which extends the axles from and retracts them to the stowed position with a more compact footprint –2.49 x 4.11 m retracted or 3.94 x 4.11 m extended.

Weighing 21,727 kg, with an overall transport length of 13.3 m, a tail swing of 1.14 m and ground clearance of 0.38 m, the Genie SX-135XC boom lift is transportable on a standard trailer; no over width or over height permits are required.

All the new Genie family of XC boom lifts will have a dual envelope design – an unrestricted lift capacity of 300 kg (660 pounds) and a restricted lift capacity of 454 kg (1,000 pounds).

Rising to the challenge posed by new safety standards

At the anniversary event, Matt Fearon, President, Terex Aerial Work Platforms, emphasized safety as a key theme moving forward and a driving force of the global AWP market. The theme of safety is especially relevant to North American customers as proposed ANSI and CSA standards are due to come into effect in 2017.

The Xtra Capacity, or XC, nomenclature lets rental customers know that this new boom complies with the overload restriction guidelines in the proposed ANSI A92 and CSA B354 industry standards in North America. Hailey noted that all Genie XC models include a new low-maintenance load-sense cell technology that monitors the weight on the platform and disables function if the load exceeds the platform load limit. “The overload sense functionalities are compensated for on all Genie XC boom models by increased platform load capacity, increasing these booms’ utilization in heavy-load applications compared to units with more restrictive platform load limits,” he said.

All Genie XC models do zero-load field calibration. The load-sense cell continuously checks the weight in the platform and adjusts the envelope to match the load chart. A tilt sensor also gives users access to different ranges of motion based on the machine’s rated slope limit, and on certain machines even on extreme angles, maximizing the ability to access more hard-to-reach work areas.