Under a midday sun, the words “Lloyd D. Nabors Demolition LLC” arced into the air along the boom of a Volvo EC460CHR ultra-high-reach excavator as it tore into the shell of a five-storey building. The machine is capable of reaching heights nearing 90 feet with a forward reach of up to 54.6 feet as its shear claw surgically snips steel and limestone columns into manageable pieces of debris.

The building was being demolished to make an open space beside a courthouse but the courthouse was just 15 feet away, with bump-outs extending 20 feet from the building. This made it nearly impossible to move large equipment on site.

“We began the demolition by hand, dismantling the five storey bump-out from top down using mini excavators hoisted onto the roof and genuine manpower,” says Lloyd Nabors, company owner and president. “That gave us an extra 20 feet of width to bring in the Volvo high-reach excavator.”

A job that would in more typical conditions take 45 days stretched to 90 due to the delicate nature of the demolition.

Steady and stable

When determining which equipment to bring to the job, Nabors, who has more than 30 years of demo experience, knew the Volvo EC460CHR that he had added to his fleet just six months earlier would be the workhorse excavator. Powered by a Volvo 329-hp engine, the 60-ton machine combines high torque at low rpms with high flow hydraulics to bring the 80,000-square-foot structure cleanly and safely to the ground with no impact on the neighbouring buildings.

“With the long reach boom fully extended, the stability of the EC460CHR is bar none. And when you are working at these heights with a LaBounty UP25 6,000-pound shear at the end of your boom, beating against a building, you need to feel stable,” says Jarred Walker with ROMCO Equipment Company, a Volvo Construction Equipment dealer.

The Volvo high-reach excavator line has the capacity to handle attachments from 5,500 to 7,720 pounds, including grapples, shears, pulverizers and hammers.

Maneuvering the Volvo high-reach demolition excavator into position was eased by the hydraulically retractable undercarriage, which can expand from 7 feet 10 inches to 11 feet 1 inch to simplify transport and increase stability and production when working. An additional 8,370-pound counterweight anchors the excavator to allow a wide operating range without diminishing control, power or stability.

“The operators absolutely love the Volvo high reach for its comfort and control. The cab tilts up to 30 degrees to prevent straining and with the on-board rearview cameras you have 360 degrees of sight. There is less mental and physical fatigue and that makes for a much less stressful job,” Nabors adds.

During the later stages of the project, crews worked up to 10 hours a day seven days a week, with the high reach doing 99 percent of the tear-down work and a Volvo EC380D and EC360C with grapples partnering to separate and scoop debris into hauler trucks. “Despite the heavier operating hours, we are using substantially less fuel than with our previous competitor high reach and seeing up to 15 percent savings over our previous high-reach excavator,” says Nabors.

Lloyd D. Nabors Demolition has evolved into a full service demo company which includes bridge demolition and asbestos abatement. “We do a lot of travelling,” Nabors says, shuttling crews hundreds of miles to demo sites.

These logistical and equipment versatility demands are what sold him on the EC460CHR.

“We had a competitor excavator with a modified long arm. It was eight years old with high hours. There were a lot of upkeep and repair issues, plus changing out the standard boom to the long arm could take up to four to five days. It was costing us in downtime and lost job opportunities,” says Nabors. “Then Jarred told me about a Volvo highreach excavator on the ROMCO lot in Fort Worth.”

Says Walker: “It was a classic case of they had a need and we had the right machine. Walter Reeves (demolition segment manager for Volvo CE) approached us about the high-reach excavator and the first person I thought could benefit was Lloyd. We put him at the controls so he could feel the stability of the machine. Then, Walt and I showed him how to switch out the high-reach boom to the digging boom in less than one hour using the modular joint system. That sold him. He had the machine on a job site two months later!”

The Volvo line of high-reach excavators uses a hydraulic, modular joint system to efficiently change from the high-reach boom to the digging boom. The modular joint allows the digging boom to be either in the straight or bent configuration for more reach height or digging depth.

“The modular joint boom has allowed us to be more diversified. When you don’t need the high reach, in less than one hour you can revert the machine to a standard excavator. It is really like having two machines in one,” Nabors says.

To minimize dust, a supersize DustBoss oscillating fan, mounted onto a truck and attached to a 1.5-inch fire hose, shoots water four to five storeys into the air, dampening the powderized concrete that hangs in the air.

Lloyd D. Nabors Demolition is a green-certified demolition company, committed to maximizing the amount of demolition materials that are recycled. This certification also allows them to contract for numerous LEED (Leadership in Energy and Environmental Design) projects.

“We treat every job as if it’s green certified,” says Nabors. “It’s an advantage to us environmentally by reducing waste, and economically in landfill fee savings. All concrete from this site is going to a local recycler where it is turned into road base. The rebar and steel columns are also recycled.”

Walker met Nabors through a mutual contractor friend who ran a Volvo fleet. Nabors was interested in the full demo guard package factory fitted by Volvo and subsequently purchased it on his first Volvo demolition excavator, a EC210B. This includes heavy-duty side doors with screen, swing-ring cover, heavy-duty undercover for the superstructure and side impact protection. The excavator is still active in his fleet and operated by his son Colton.

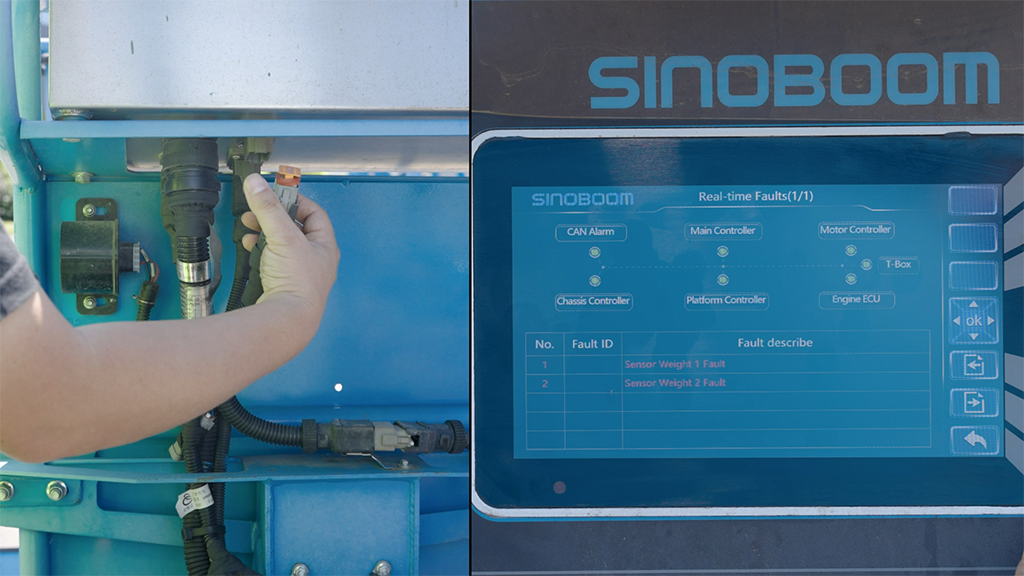

With CareTrack telematics activated on several units, including the EC460CHR, ROMCO service technicians receive maintenance and operational alerts so they can bring the right parts out to the job site on the first trip and improve uptime. The CareTrack system also allows Nabors to monitor fuel consumption and operating hours in realtime and review machine diagnostic history.

Today Lloyd D. Nabors Demolition counts 10 excavators in its fleet, including one EC460CHR, three EC380Cs, three EC360Cs, one EC340C, one EC290, and the original EC210B. All were purchased through Volvo Financial Services.