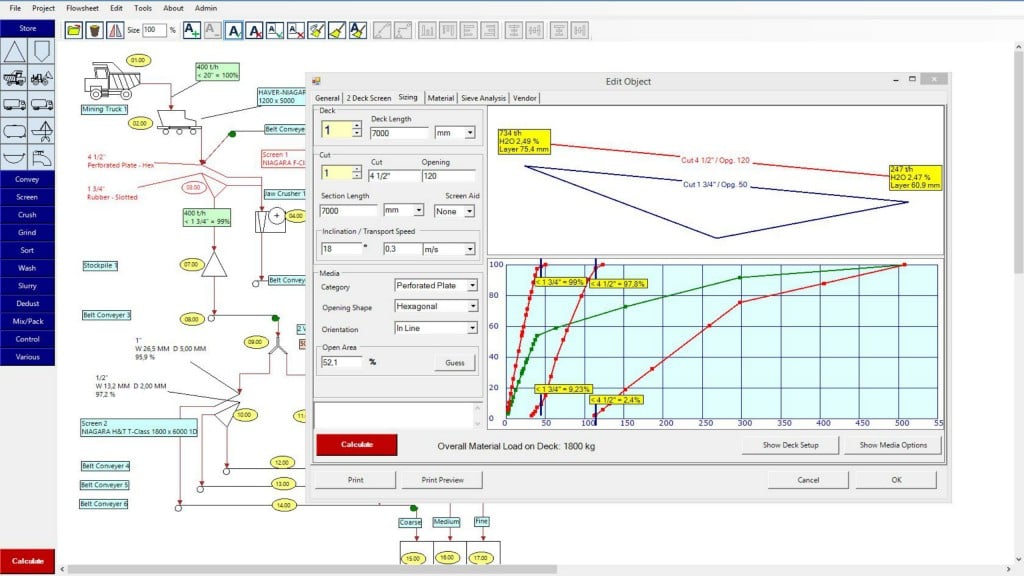

Haver & Boecker has introduced NIAflow plant simulation software. NIAflow helps producers optimize quarry and mine operations by diagramming plant flow, machine placement, product pre-calculations and more.

Haver & Boecker will feature NIAflow September 26-28 at booth 12050 during MINExpo International in Las Vegas.

Developed by Haver & Boecker engineers, NIAflow instantly analyzes existing or proposed processes, records plant statuses, and recognizes potential for plant optimization. The software is available for download on Windows-based systems. NIAflow supports the user in every engineering phase, from drafting flow diagrams for product pre-calculation to plant startup and simulating parameter changes. Its intuitive menu control makes it easy for all levels of experience, and Haver & Boecker provides several levels of training, if needed. These can be group, company or even individual training sessions.

“As part of our ongoing efforts to optimize plant efficiency for our customers, we are constantly developing innovative machines, programs and software to help them be successful,” said Karen Thompson, president of Haver & Boecker Canada. “NIAflow will serve as a cornerstone in the development of process engineering projects. When paired with other Haver & Boecker technology, such as Pulse vibration analysis software, our customers will hold all of the tools they need to optimize process flow and increase productivity and profits.”

NIAflow allows users to analyze more than 90 different process equipment pieces, from crushers and vibrating screens to material washers and conveyers. Beyond equipment, the system uses scientific-based methods to monitor the operation’s input, output and waste piles. The program calculates the mass and volumetric flow rates as well as the valuable content with machine-specific operating parameters to prevent plant bottlenecks before equipment is in place.

“NIAflow will significantly impact the efficiency and profitability of our mineral processing customers,” said Joachim Hoppe, Haver & Boecker Mining general manager. “The thought process behind this software development was to give our partners tools to closely monitor their plant setup as a whole, allowing them to identify problems and plant bottlenecks. NIAflow helps producers discover the most efficient setup for existing equipment as well as determine equipment needed to enhance productivity and increase production.”

NIAflow is available for purchase for aggregates and mining. The NIAflow Aggregates version is the extensive, full version of the NIAflow simulation software that allows unlimited machine input. NIAflow Mining complements the Aggregates full version, but offers additional equipment options, such as classifying and sorting equipment.

A basic, complementary version of NIAflow is available for download at www.niaflow.com.

Company info

225 Ontario St.

St. Catharines, ON

CA, L2R 7B6

Website:

haverniagara.com

Phone number:

1-905-688-2644