FPT Industrial's broad range of engine offerings on display at ARA Show

FPT Industrial will showcase its full range of 2.8- to 16-litre Tier 4 Final and Stage V engines suitable for the rental industry at the ARA Show in New Orleans, LA. The engine portfolio offers performance along with flexibility, reliability, and low cost of ownership in compact engine layouts.

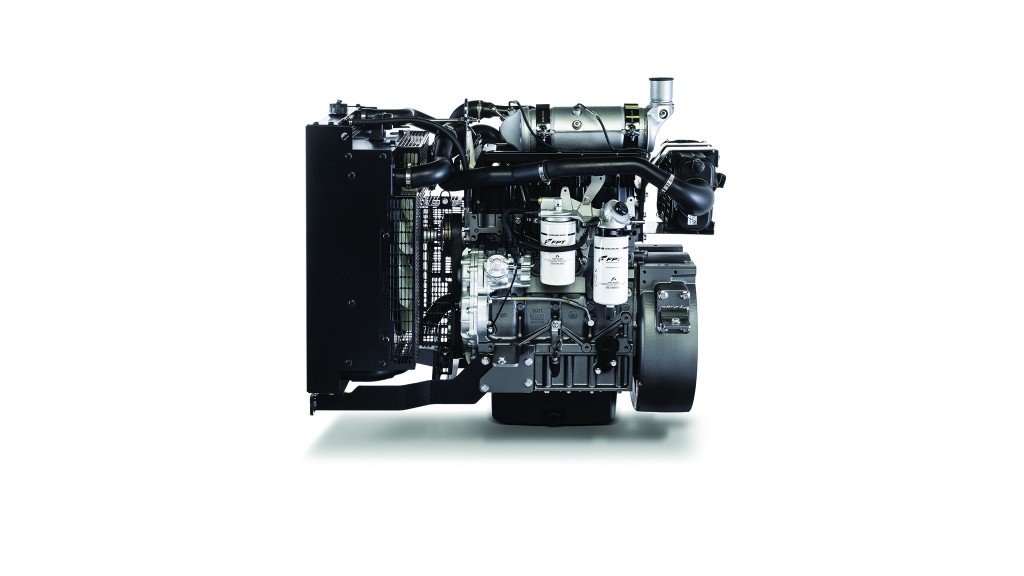

FPT will display the F28 Tier 4 Final/Stage V Powerpack, the F36 Tier 4 Final/Stage V Powerpack, the NEF67 Tier 4 Final with ATS Pack, and the C16 Tier 4 Final engines during the show.

The extensive FPT Industrial engine line for industrial and power needs allows rental companies to simplify their operations to one engine provider and reduce their operational complexity. Most FPT engines allow for single-side access for easy and quick maintenance, while 600-hour service intervals maximize uptime. For use in gensets, the engines are less complex and provide reliable energy sources.

"We have been working within North America for a number of years now, developing a new line of engines to fit equipment manufacturers' specific needs, similar to what we've done for CASE and New Holland. We're here at the ARA Show to bring our innovative power solutions directly to the rental market," stated Braden Cammauf, Vice President, North America FPT Industrial Commercial Operations. "We have been working with our customers to provide our high-performance engines that meet emission standards, and lead the market in reduced maintenance costs through technological innovations. Our Tier 4 Final engines are DPF-free, offer 600-hour service maintenance intervals, and provide the power within a compact footprint that makes it easier to install into equipment."

A number of patented technologies make a big difference for FPT Industrial engines. The DPF-free HI-eSCR aftertreatment technology helps to maximize uptime and reduce operating costs. For Tier 4 Final/Stage V compliance FPT Industrial offers the HI-eSCR2 aftertreatment components packed in a compact, fully enclosed structure. This allows for more flexible layout and simpler installation.

Another patented feature, electronically controlled exhaust flaps, maximize performance at low temperature and low load, avoiding the need for additional load banks. Improved exhaust gas temperature control speeds up SCR light-off in the cold part of the emission cycle through an electronically controlled exhaust flap.

All FPT Industrial Tier 4 Final and Stage V engines are compatible with diesel and parafinnic/renewable fuels like HVOs. Combined with FPT Industrial's ATS technology, the low-emission and sustainable solution has reduced CO2 impact by up to 90 percent.

With more than 80,000 units sold globally and more than 20 years of experience, FPT Industrial is leading the introduction of natural gas and methane technology in on-road and off-road segment applications. It has also begun to produce e-powertrains and battery packs for use in multiple applications. Field testing is underway of a 13-litre hydrogen engine in a Prinoth snow groomer.

The F28 engine family offers the performance of a 3.4-litre engine in a 2-litre package, providing performance in a smaller space. The F28 PowerPack is compact and pre-validated, including all key aftertreatment components, simplifying installation. Oil change intervals of 600 hours contribute to lower operating costs. It has a modular, multi-fuel design that shares common base components with diesel, natural gas, and scalable hybrid versions. Max power is 75 hp.

The F36 PowerPack is a powerful, flexible, and reliable Tier 4 Final/Stage V solution for stationary and semi-stationary applications. The compact ATS pack installed on the engine, including the urea injection system and all required sensors and manifolds, eliminates the need for development of a dedicated exhaust system. A range of options like starters, alternators, water and air preheating, and different urea tank sizes provide further flexibility. The F36 can produce up to 141 hp.

Designed for he most demanding customer requirements, the N67 is compact and features the maintenance-free ATS Pack as a pre-assembled, pre-wired, and pre-validated solution for flexible, fast, and easy installation and labour savings. Downtime is minimized with 600-hour service intervals and FPT Industrial's "for life" maintenance-free technology. Maximum power in off-road use is 284 hp.

Delivering 18-litre performance in a 16-litre package, the Cursor 16 is the flagship of the Cursor range. High torque availability ensures fast load response for maximum in-field productivity. The C16 is dependable and compact, with a high power-to-weight ratio, 2200 bar common rail system, ball-bearing turbocharger, and a high-resistance cylinder head in compacted graphite iron. It has a maximum output of 700 hp.

FPT Industrial and its dealer network use modern technologies to deliver 360-degree professional assistance to maximize uptime and minimize total cost of ownership. The MyFPT app provides customers health information on their engines and equipment at the touch of a finger, along with quick, efficient, tailored support. Connecting a plug-and-play FPT dongle to the machine engine diagnostic port and connecting via Bluetooth allows users to gather engine data in real time, optimizing daily usage and confirming engine status.