Kohler Direct Injection Hydrogen engine designed to match diesel performance

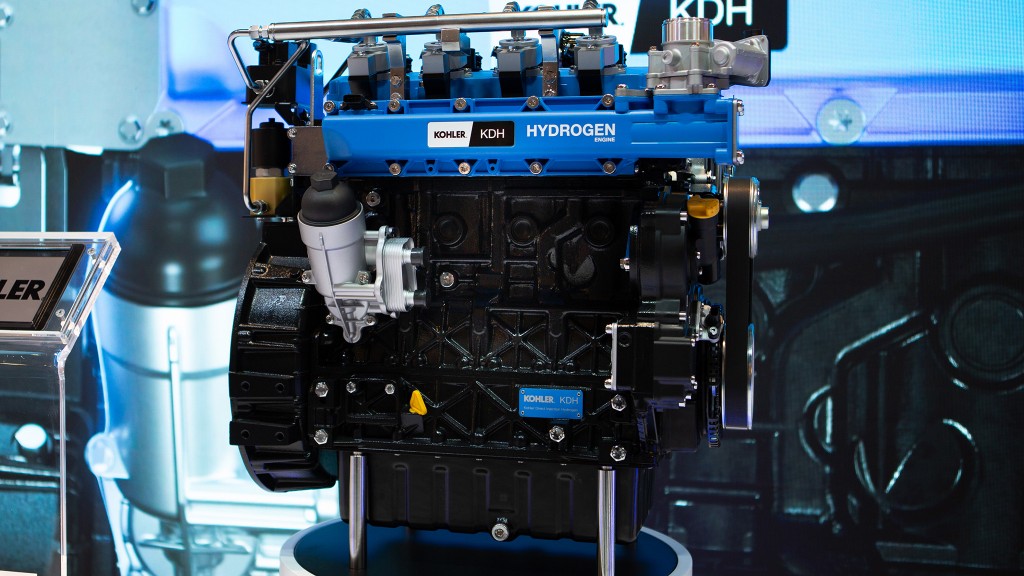

Kohler Engines has launched its Direct Injection Hydrogen (KDH) engine, an internal combustion engine running on hydrogen, as part of its efforts to develop new technologies with reduced environmental impact.

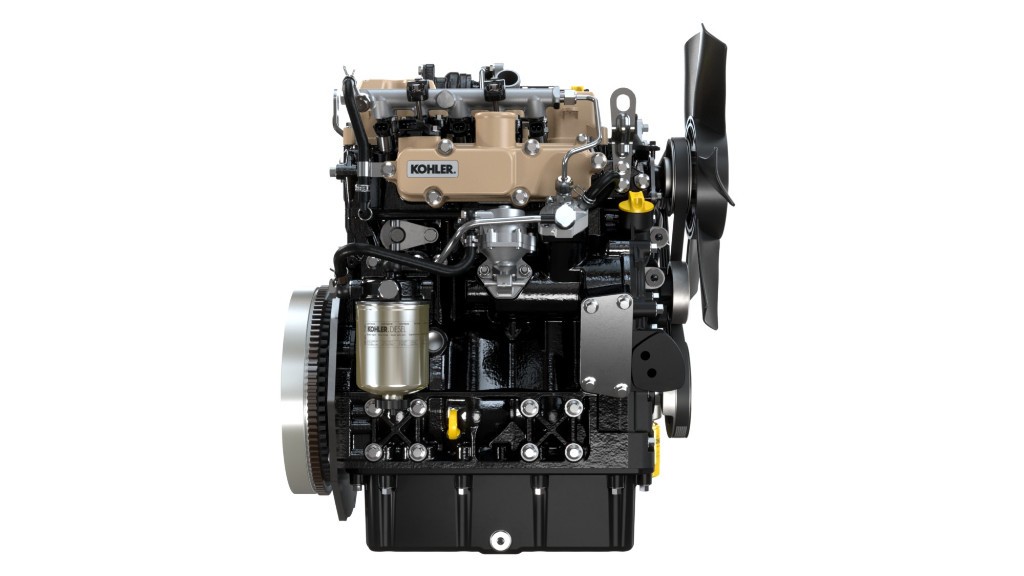

The new hydrogen technology is being applied to the KDI 2504 TCR engine and will take advantage of conventional combustion engine architecture but replace diesel with hydrogen. The engine, a 74-hp unit, will maintain its installation, dimensions, PTOs, and performance, Kohler says, while becoming a zero-carbon solution.

Kohler has worked with a number of technologies to enhance energy efficiency for diverse machinery requirements. Hydrogen has emerged as a versatile, green energy fuel with rapidly evolving technology. It has a wide flammability range, high flame speed, low ignition energy, and high diffusivity, giving it promise as a cleaner alternative fuel for internal combustion engines.

Combustion in a hydrogen engine is cleaner than a standard diesel engine. When an aftertreatment system is applied, the environmental benefits of a hydrogen engine are amplified, Kohler states, making it near zero-emission. Aftertreatment reduces particulate matter, nitrogen oxides, and hydrocarbons all to negligible levels at the tailpipe. This dual approach complies with emission standards and underscores the commitment to cleaner air quality.

Direct injection technology, as opposed to port fuel injection, allows the ability to preserve diesel performance, including transient response, by avoiding the backfire problem. Kohler's design aims to provide the same performance as the original diesel engine, including max power, peak and low-end torque, and transient response and drivability, all allowing maximum equipment productivity.

The new hydrogen internal combustion engine is designed to be a drop-in solution, making it potentially adaptable to a range of applications. Kohler has focused on making no major changes to the engine compartment, and the new engine has the same envelope as the KDI diesel. The engine platform of the machine retains the same cooling circuit, power take-off and flywheel, engine mounting points, and intake line. In addition, aftertreatment is not required in Stage V, Kohler notes.