New diesel engines offer up to 800 kVA for gensets

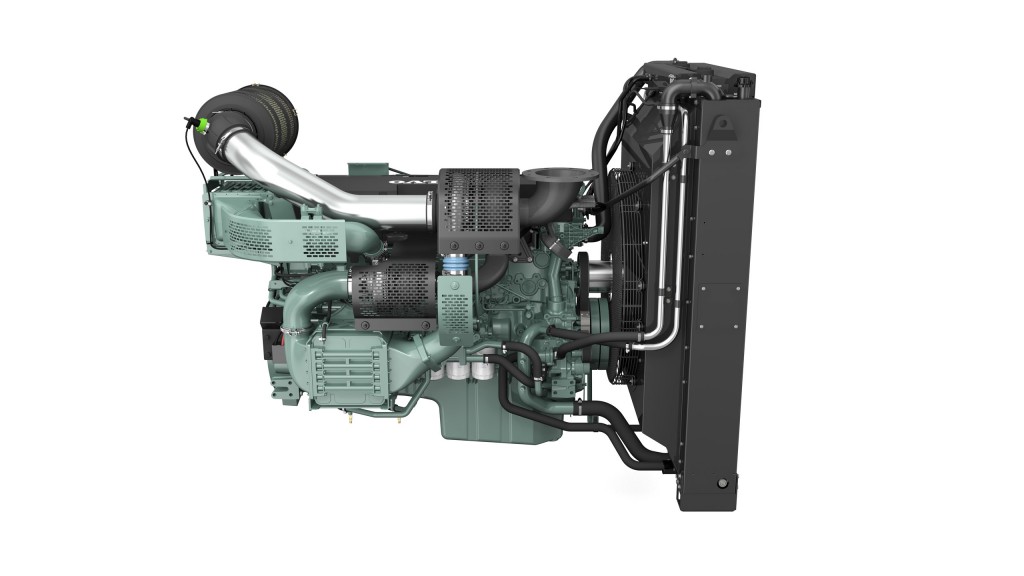

Volvo Penta is launching two new diesel engines – one of which has the highest power density engine per liter of displacement in its class. The TWD1645GE and TWD1644GE engines extend Volvo Penta’s competitive range and reinforce the company’s commitment to international genset customers.

Volvo Penta is taking a significant step forward by adding new technology and upgraded features to its new power generation engines. The 16-litre TWD1645GE has been designed to produce up to 10 per cent more power compared to previous models to offer a world class leading independent power source. Its switchable rpm settings mean that it can be used anywhere in the world.

“This is an exciting move for us to be launching the highest power density engine in its class,” says Giorgio Paris, head of Volvo Penta’s industrial segment. “We are setting a new standard in power generation with our market-leading offer. The engine comes equipped with our latest features, which enable us to deliver the most power per litre displacement of any 16-litre engine on the market.”

Efficient power density

The TWD1645GE produces up to 800 kVA at 1800 rpm (60 Hz), and up to 770 kVA at 1500 rpm (50 Hz.). Its sister model, the TWD1644GE produces up to 752 kVA at 1800 rpm, and up to 717 kVA at 1500 rpm. Both are calculated with 94 per cent generator efficiency.

“We have achieved this level of market-leading power density by advancing our technology and adding new features,” says Krikor Abraham, Volvo Penta’s product manager for the power generation segment. “We are able to leverage more power out of the engines, and customers will see a range of benefits.”

The new 16-litre engines feature: dual stage turbo-chargers and new high grade steel pistons, for excellent power density; optimized combustion with electronic high-pressure unit injectors, resulting in high fuel efficiency and low exhaust emission levels; upgraded wiring harness, for optimum insulation in harsh environments; two-circuit cooling package; and an advanced engine control system.

The engine can be used for prime power, in locations such as construction sites where there is no electricity grid supply, and as standby power, for sites such as hospitals which require back-up electricity supply in the event of normal power failure.