Wirtgen releases new TCM 180i Texture Curing Machine boosting concrete pavement quality

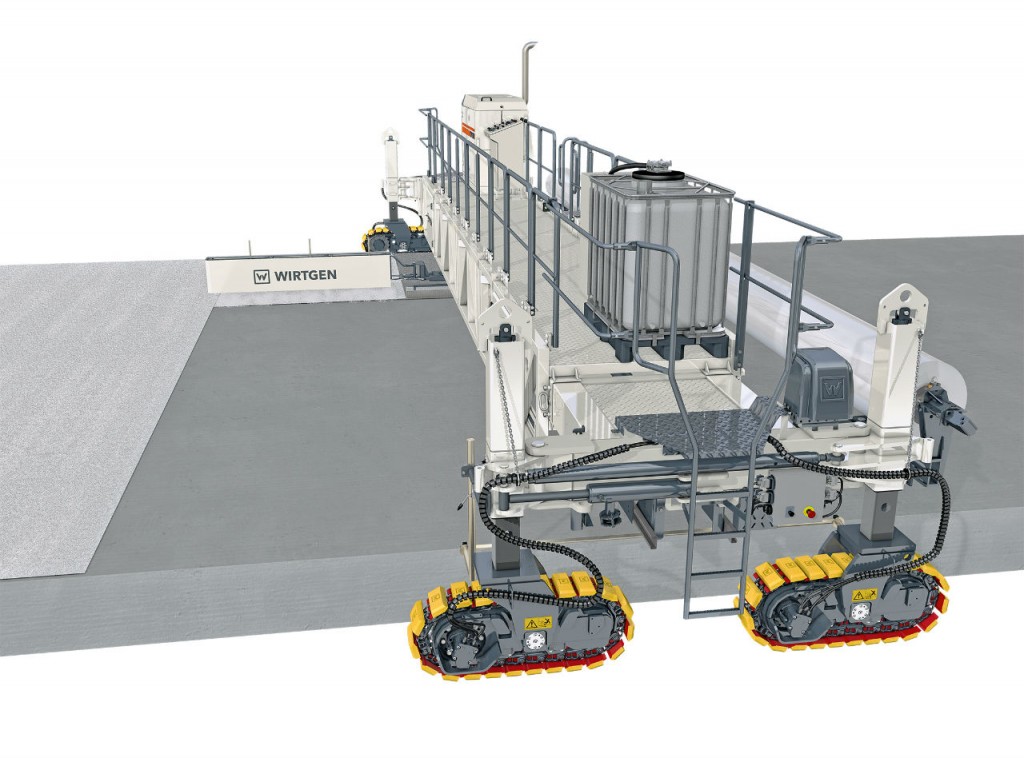

Self-propelled curing units, such as the new TCM 180i from Wirtgen, guarantee the success of professionally cured concrete pavements.

The modular four-track design of the the new TCM 180i permits working widths between 13 ft., 1 in. (4 m) and 59 ft., 1 in. (18 m), with hydraulic leg swing that allows for mobilizing into transport configuration in minutes

A new engine unit means that the TCM 180i now has the most eco-friendly engine technology in compliance with emission level EU Stage 4 / U.S. Tier 4 Final.

With its new operating concept, the curing unit can now be operated intuitively, just like the Wirtgen slipform pavers of the SP 90i and SP 60i series. In addition to a more modern and clearer arrangement, the operator's console also features a number of new service and control functions, optimizing the work process with enhanced visibility and operator access across the entire width of the unit.

Its new hydraulic concept also has a positive impact on the work process, as the traction drive can now be switched at different speeds, for example, between working and transport mode. Proportional control supports precision height adjustment to meet every requirement.

Additionally, Wirtgen has enlarged its range of different surface textures to cater to the diverse wishes of its customers around the world. In addition to the established functions of transverse brooming (texturing) and spraying, longitudinal brooming (texturing) and spraying – and even the application of a diagonal finish – now is possible. The machine also can be fitted with mounts for a burlap or synthetic turf.

A film unwinding device (known as a Polyroll) helps to protect the concrete quickly and effectively from the negative effects of sudden rain. Traveling in reverse gear directly behind the slipform paver, the machine spreads plastic sheeting to protect the concrete from rain.

Company info

6030 Dana Way

Antioch, TN

US, 37013

Website:

wirtgen-group.com/en-us

Phone number:

615-501-0600